Increased Focus on Lightweight Materials

The Atomizing Metal Powder Market is witnessing a heightened focus on lightweight materials, particularly in the aerospace and automotive sectors. The push for fuel efficiency and reduced emissions is prompting manufacturers to explore advanced materials that can deliver performance without adding weight. Atomized metal powders, such as aluminum and titanium, are increasingly favored for their strength-to-weight ratios. The market for lightweight materials is projected to grow significantly, with estimates suggesting a CAGR of over 10% in the coming years. This trend indicates a promising outlook for the Atomizing Metal Powder Market, as it aligns with the broader industry shift towards sustainable and efficient manufacturing practices.

Growing Adoption of Additive Manufacturing

The Atomizing Metal Powder Market is significantly benefiting from the growing adoption of additive manufacturing technologies. As industries increasingly embrace 3D printing for metal components, the demand for high-quality atomized metal powders is on the rise. This manufacturing method allows for complex geometries and reduced material waste, appealing to sectors such as healthcare, aerospace, and tooling. Reports suggest that the additive manufacturing market is expected to grow at a CAGR of around 25% over the next five years, which will likely drive the demand for atomized metal powders. Consequently, the Atomizing Metal Powder Market is poised for substantial growth as it aligns with the evolving manufacturing landscape.

Innovations in Powder Production Technologies

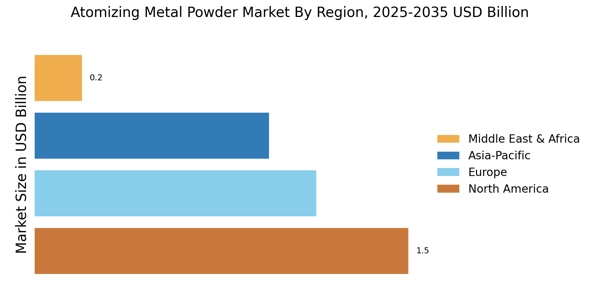

Technological advancements in powder production methods are significantly influencing the Atomizing Metal Powder Market. Innovations such as gas atomization and water atomization are enhancing the quality and consistency of metal powders, making them more suitable for various applications. For instance, gas atomization allows for the production of finer powders with uniform particle size distribution, which is essential for high-performance applications. The market for atomized metal powders is expected to reach USD 1.5 billion by 2026, reflecting the impact of these technological improvements. As manufacturers continue to invest in research and development, the Atomizing Metal Powder Market is likely to witness further enhancements in production efficiency and product quality.

Regulatory Support for Advanced Manufacturing

The Atomizing Metal Powder Market is benefiting from regulatory support aimed at promoting advanced manufacturing techniques. Governments are increasingly recognizing the importance of additive manufacturing and its potential to enhance productivity and innovation. Initiatives that provide funding and resources for research in metal powder technologies are likely to stimulate growth in the Atomizing Metal Powder Market. For example, various countries have introduced policies to support the development of advanced materials and manufacturing processes, which could lead to increased investments in atomized metal powder production. This regulatory environment appears conducive to the expansion of the Atomizing Metal Powder Market, fostering innovation and competitiveness.

Rising Demand in Aerospace and Automotive Sectors

The Atomizing Metal Powder Market is experiencing a notable surge in demand, particularly from the aerospace and automotive sectors. These industries are increasingly adopting advanced manufacturing techniques, such as additive manufacturing and 3D printing, which require high-quality metal powders. The aerospace sector, for instance, is projected to grow at a compound annual growth rate (CAGR) of approximately 5.5% over the next few years, driving the need for specialized metal powders. Similarly, the automotive industry is shifting towards lightweight materials to enhance fuel efficiency, further propelling the demand for atomized metal powders. This trend indicates a robust growth trajectory for the Atomizing Metal Powder Market, as manufacturers strive to meet the evolving requirements of these critical sectors.