Expansion of the Construction Industry

The Chrome Metal Powder Market is benefiting from the expansion of the construction industry, where chrome metal powder is used in various applications, including coatings and surface treatments. The construction sector is experiencing a resurgence, driven by urbanization and infrastructure development projects. As the demand for durable and corrosion-resistant materials increases, chrome metal powder is likely to see heightened usage in construction applications. Reports indicate that the construction industry is expected to grow at a rate of approximately 5% annually, which could significantly impact the demand for chrome metal powder, thereby contributing to the overall market growth.

Rising Demand from the Electronics Sector

The Chrome Metal Powder Market is witnessing a rising demand from the electronics sector, where chrome metal powder is utilized in the production of conductive inks and coatings. The electronics industry is projected to grow at a steady pace, with an increasing focus on miniaturization and enhanced performance of electronic components. Chrome metal powder's conductive properties are essential for developing high-performance electronic devices, which are becoming increasingly prevalent in consumer electronics, automotive applications, and industrial machinery. This trend indicates a robust potential for growth in the chrome metal powder market, as manufacturers strive to meet the evolving needs of the electronics sector.

Growing Focus on Environmental Sustainability

The Chrome Metal Powder Market is increasingly influenced by a growing focus on environmental sustainability. Manufacturers are under pressure to adopt eco-friendly practices, which includes the use of sustainable materials and processes. Chrome metal powder, when produced using environmentally responsible methods, can contribute to reducing the carbon footprint of various applications. The market is likely to see a shift towards more sustainable production techniques, which may enhance the appeal of chrome metal powder in industries that prioritize sustainability. This trend could potentially drive demand and foster innovation within the chrome metal powder market.

Technological Advancements in Powder Metallurgy

The Chrome Metal Powder Market is being propelled by technological advancements in powder metallurgy, which enhance the production processes and quality of chrome metal powders. Innovations in manufacturing techniques, such as improved atomization methods and advanced sintering technologies, are likely to lead to higher purity and finer particle sizes of chrome metal powder. These advancements not only improve the performance characteristics of the powder but also expand its applicability across various industries, including automotive and aerospace. As these technologies continue to evolve, they may create new opportunities for growth within the chrome metal powder market.

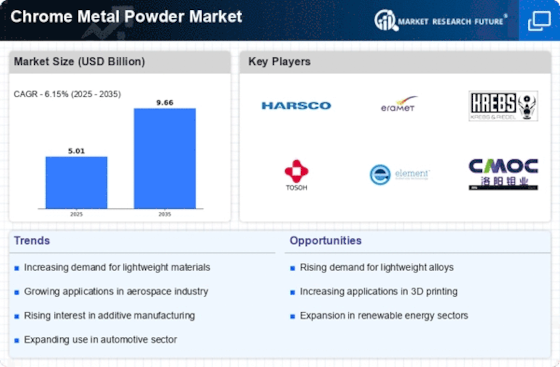

Increasing Applications in Additive Manufacturing

The Chrome Metal Powder Market is experiencing a notable surge in demand due to its increasing applications in additive manufacturing, particularly in 3D printing technologies. This sector is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 25% in the coming years. The unique properties of chrome metal powder, such as its high melting point and excellent corrosion resistance, make it an ideal choice for producing complex geometries in various industries, including aerospace and automotive. As manufacturers seek to optimize production processes and reduce material waste, the adoption of chrome metal powder in additive manufacturing is likely to expand, thereby driving the overall market growth.