Market Analysis

In-depth Analysis of US Warehouse Robotics Market Industry Landscape

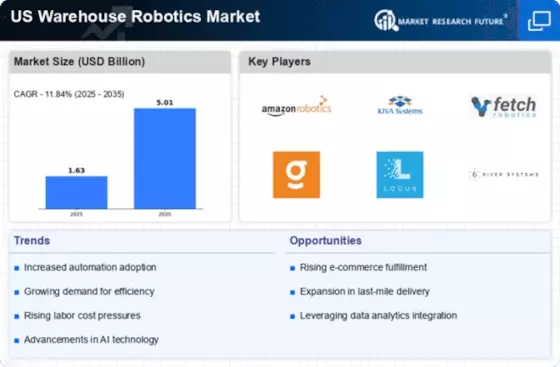

The US warehouse robotics market has experienced a transformative evolution driven by the intersection of technology and logistics. In recent years, the demand for warehouse automation solutions has surged, catalyzing a dynamic shift in market dynamics. One of the primary drivers behind this trend is the need for increased efficiency and cost-effectiveness in the supply chain. As e-commerce continues to flourish, businesses are compelled to adapt to the rapid growth in order fulfillment requirements. This has propelled the adoption of warehouse robotics to streamline operations, enhance order accuracy, and reduce labor costs.

The competitive landscape of the US warehouse robotics market is marked by the presence of a diverse range of players, including both established industry giants and innovative startups. Major companies such as Amazon Robotics, KUKA AG, and Daifuku Co., Ltd., have played pivotal roles in shaping the market. These companies offer a spectrum of robotic solutions, ranging from autonomous mobile robots (AMRs) for material handling to robotic arms for picking and packing tasks. The diversity in product offerings underscores the dynamic nature of the market, as companies strive to meet the varied demands of different industries and applications.

Technology advancements have been a key catalyst in the evolution of warehouse robotics. The integration of artificial intelligence (AI), machine learning, and computer vision has empowered robots with the ability to navigate complex warehouse environments, make real-time decisions, and adapt to changing circumstances. This has significantly enhanced the flexibility and versatility of warehouse robotics, making them capable of handling diverse tasks with precision. The integration of advanced sensors and data analytics further contributes to the optimization of warehouse operations, providing valuable insights for continuous improvement.

A noteworthy trend in the market is the increasing collaboration between warehouse robotics providers and end-users. This collaborative approach allows for the customization of robotic solutions to meet specific operational requirements. Companies are actively seeking partnerships to co-create innovative solutions that address their unique challenges. This trend is fostering a symbiotic relationship wherein the expertise of warehouse robotics providers converges with the operational insights of end-users, resulting in tailored solutions that deliver maximum value.

The market dynamics are also influenced by regulatory factors and safety considerations. As robots become integral to warehouse operations, there is a growing emphasis on establishing industry standards and regulations to ensure the safe interaction between humans and robots. Companies are investing in developing and implementing robust safety protocols to mitigate risks and build trust in the widespread adoption of warehouse robotics.

The COVID-19 pandemic has further accelerated the adoption of warehouse robotics, as it highlighted the vulnerabilities of traditional supply chain models. The need for resilient and agile supply chains has driven companies to invest in automation solutions that can withstand disruptions and ensure business continuity. Warehouse robotics, with their ability to operate 24/7 and adapt to changing demand patterns, have emerged as a strategic asset in building more resilient supply chains.

Leave a Comment