Top Industry Leaders in the Steel Processing Market

The steel processing market, encompassing activities like cutting, bending, coating, and finishing raw steel into usable forms, pulsates with fierce competition. Understanding this landscape requires delving into dominant players, their strategies, and the evolving market dynamics.

Competitive Strategies Shaping the Market:

-

Diversification and Specialization: Market leaders like ArcelorMittal and POSCO are expanding their product portfolios, catering to niche applications in industries like automotive and energy. Meanwhile, regional players like NACHI-FUJIKOSHI CORP. are carving out unique positions by specializing in advanced processing technologies like laser cutting and high-precision machining.

-

Technological Prowess: Automation and digitalization are key differentiators. Companies like Sandvik AB and Kennametal Inc. are investing heavily in AI-powered process optimization, robotic handling systems, and advanced simulation software, offering customers increased efficiency and precision.

-

Sustainability Focus: Green credentials are becoming a crucial competitive edge. Baosteel Group Corporation and Angang Steel Company are leading the charge with eco-friendly processing technologies like cleaner production methods and resource recycling, winning favor with environmentally conscious buyers.

-

Geographical Expansion: Emerging markets hold immense potential. Tata Steel Ltd. and United States Steel are aggressively expanding their footprint in Asia and Africa, capitalizing on the burgeoning infrastructure and construction sectors in these regions.

-

Strategic Partnerships and Acquisitions: Collaborations and mergers are accelerating innovation and market reach. Recent examples include NSK Ltd.'s partnership with Thyssenkrupp AG to develop next-generation bearings for automotive applications and voestalpine High Performance Metals GmbH's acquisition of B*Steel, strengthening its position in the high-performance steel segment.

Factors Determining Market Share:

Cost Competitiveness: Efficient production processes, optimized supply chains, and access to low-cost raw materials play a crucial role in winning price-sensitive contracts.

Product Quality and Consistency: Consistent delivery of high-quality steel processed to precise specifications is paramount for customer satisfaction and repeat business.

Customer Service and Innovation: Proactive customer support, customized solutions, and a commitment to developing cutting-edge processing technologies can differentiate players in a crowded market.

Geographical Presence: Being present in key steel-consuming regions and having strong local distribution networks are vital for capturing market share.

Environmental Friendliness: Sustainability practices are becoming increasingly important, with customers increasingly favoring companies with a strong commitment to reducing their environmental impact.

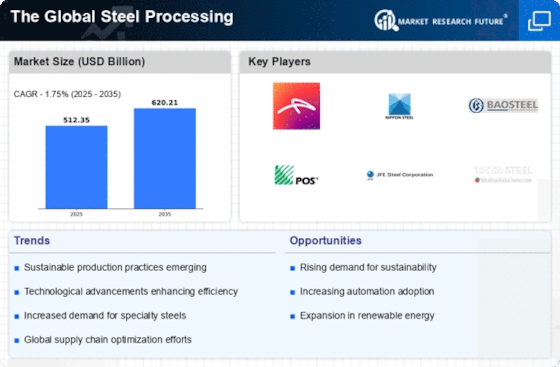

Key Companies in the Steel Processing market include

- Steel Authority of India Limited (SAIL)

- TATA Steel Ltd.

- JSW Steel

- NSK Limited

- POSCO

- Baosteel Group Corporation

- Angang Steel Company

- Sandvik AB

- Nippon Steel & Sumitomo Metal Corporation

- Hudson Tool Steel Corporation

Recent Developments:

October 2023: The US and EU agree to suspend steel and aluminum tariffs for two years. This is seen as a positive development for the global steel industry, as it could help to reduce trade tensions and boost demand.

November 2023: Steel prices begin to fall after reaching record highs earlier in the year, due to concerns about a global economic slowdown and reduced demand from China.

December 2023: POSCO, South Korea's largest steel producer, announces a partnership with Hyundai Steel to develop new steel products for the automotive industry.