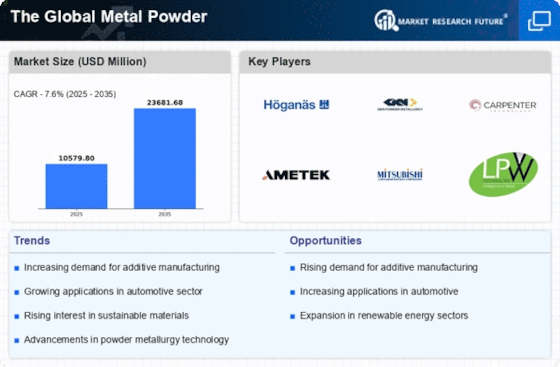

Top Industry Leaders in the Metal Powder Market

Beyond the gleaming facades of skyscrapers and the whirring gears of machines lies a hidden yet transformative force – the Metal Powder market. These fine, versatile particles breathe life into diverse applications, from intricate automotive components to high-performance medical implants. But beneath the seemingly uniform layer of metallic dust lies a vibrant ecosystem where established giants and innovative startups grapple for market share amidst evolving trends, technological advancements, and environmental concerns. Let's delve deeper and explore the strategies, factors, and recent developments shaping this transformative market.

Beyond the gleaming facades of skyscrapers and the whirring gears of machines lies a hidden yet transformative force – the Metal Powder market. These fine, versatile particles breathe life into diverse applications, from intricate automotive components to high-performance medical implants. But beneath the seemingly uniform layer of metallic dust lies a vibrant ecosystem where established giants and innovative startups grapple for market share amidst evolving trends, technological advancements, and environmental concerns. Let's delve deeper and explore the strategies, factors, and recent developments shaping this transformative market.

Strategies Forging Market Dominance:

-

Product Diversification: Leading players like Höganäs AB, Sandvik Osprey, and AP&C Inc. are constantly refining their offerings, developing customized metal powders with tailored properties for specific applications. Think high-strength powders for aerospace components, biocompatible powders for medical implants, and corrosion-resistant powders for marine environments. -

Sustainability Focus: Environmental consciousness is influencing the market. Players are adopting energy-efficient production processes, exploring recycled materials, and developing metal powders with improved recyclability to minimize environmental impact and cater to eco-conscious consumers. -

Vertical Integration: Securing reliable sources of key raw materials like metal ores and reducing dependence on fluctuating prices is crucial. Companies like Carpenter Technology and Molytek are investing in backward integration to gain control over the supply chain and optimize costs. -

Geographical Expansion: Emerging economies in Asia and Africa present immense growth potential, driven by rapid industrialization and rising disposable incomes. Companies like AMETEK and China Molybdenum Co. Ltd. are establishing production facilities and forging partnerships in these regions to capitalize on this trend.

Factors Fueling Market Growth:

-

End-User Industries: Automotive and medical technology remain the primary drivers, consuming over 60% of global metal powder production. Rising demand for lightweight vehicles and personalized medical devices contributes to this demand. -

Additive Manufacturing (AM) Revolution: The explosive growth of 3D printing technologies like metal powder bed fusion and laser metal deposition fuels the need for high-quality, high-performance metal powders. Players developing powders tailored for specific AM applications stand to benefit significantly. -

Technological Advancements: Research and development efforts are leading to novel atomization techniques, improved powder handling technologies, and the development of functionalized metal powders with unique properties. Early adopters and innovators stand to gain a competitive edge. -

Resource Availability and Sustainability: Fluctuations in the prices and availability of key raw materials, coupled with increasing pressure to minimize environmental impact, drive the development of resource-efficient production processes and the exploration of alternatives like recycled metal powders.

Key Companies in the Metal Powder market include

- Sandvik AB (Sweden)

- Carpenter Technology Corporation (U.S.)

- Hoganas AB (Sweden)

- GKN Plc. (U.K.)

- Rio Tinto (U.K.)

- Allegheny Technologies Incorporated (U.S.)

- American Chemet Corporation (U.S.)

- Carl Schlenk AG (Germany)

- Hitachi Chemical Co., Ltd (Japan)

- Metaldyne Performance Group Inc (U.S.).

Recent Developments:

-

September 2023: The US Food and Drug Administration (FDA) proposes stricter regulations on metal powder safety for medical implants, prompting research into biocompatible and corrosion-resistant materials. -

October 2023: Höganäs AB unveils a new line of lightweight, high-strength aluminum powders specifically designed for automotive applications, contributing to fuel efficiency and performance improvements. -

November 2023: A consortium of leading universities, manufacturers, and AM companies launches a collaborative project to develop standardized protocols for metal powder characterization and qualification, aiming to optimize AM printing processes and improve product quality. -

December 2023: The Metal Powder market exhibits cautious optimism for continued growth in 2024, driven by rising demand, technological advancements, and a growing focus on sustainability. However, uncertainties in resource availability and evolving regulations require careful monitoring.