Market Trends

Key Emerging Trends in the Hydrodesulfurization Catalysts Market

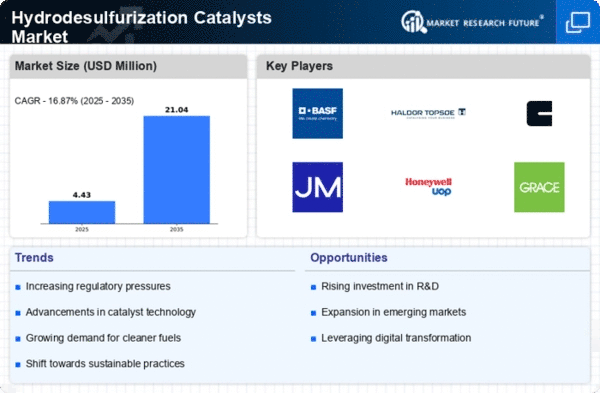

The hydrodesulfurization (HDS) catalysts market has been experiencing notable trends driven by the increasing demand for cleaner fuels, stricter environmental regulations, and advancements in refining technologies. Hydrodesulfurization is a crucial process in the petroleum refining industry aimed at reducing the sulfur content in crude oil and refined fuels to meet environmental standards and improve fuel quality. One significant trend in the HDS catalysts market is the growing demand for catalysts with higher activity, selectivity, and stability to achieve more efficient sulfur removal and reduce the sulfur content in fuels to ultra-low levels. As environmental regulations become more stringent worldwide, there is a rising need for advanced HDS catalysts capable of achieving stringent sulfur specifications while minimizing the formation of undesirable by-products and maintaining operational stability.

The purpose of removing the sulfur from these fuel oils and natural gas is to reduce the sulfur dioxide emissionsresulting fromseveral combustions. In the catalystic reforming units, the removal of sulfur is important as it can poisons the noble metal catalysts such as rhenium and platinum, evn at low concentrations. These are subsequently used to upgrading the octane rating of the naphtha streams. Damage to these precious metal catalysts can severely impact the process and leading tohigh costs.

Moreover, technological advancements are driving innovation in the HDS catalysts market, leading to the development of novel catalyst formulations and reactor designs to enhance performance and efficiency. Manufacturers are investing in research and development efforts to optimize catalyst composition, pore structure, and active sites to improve sulfur removal efficiency, increase catalyst longevity, and reduce operating costs. Additionally, advancements in catalyst support materials, promoters, and metal loading techniques are enabling the production of HDS catalysts with enhanced resistance to deactivation and poisoning by contaminants, such as nitrogen compounds and heavy metals, improving overall catalyst performance and reliability.

Furthermore, the HDS catalysts market is witnessing growth due to increasing demand from the petroleum refining industry for sulfur removal solutions to produce cleaner fuels that comply with stringent environmental regulations. With growing concerns over air pollution and its impact on public health and the environment, governments worldwide are implementing regulations to limit sulfur emissions from transportation fuels, such as gasoline and diesel. As a result, petroleum refiners are investing in HDS catalysts and refining processes to reduce sulfur levels in fuels to meet regulatory requirements and improve air quality, driving market growth for HDS catalysts.

However, the HDS catalysts market also faces challenges such as fluctuating crude oil prices, refinery capacity expansions, and competition from alternative desulfurization technologies. Fluctuations in crude oil prices can impact refinery margins and investment decisions for upgrading refining processes and installing new HDS units. Additionally, refinery capacity expansions and new investments in hydrocracking and hydrotreating technologies may affect the demand for HDS catalysts, as some refineries may opt for alternative desulfurization technologies that offer higher flexibility and processing capabilities. Moreover, competition from alternative desulfurization technologies such as adsorption, oxidation, and solvent extraction poses challenges for market penetration and pricing competitiveness for HDS catalysts.

Leave a Comment