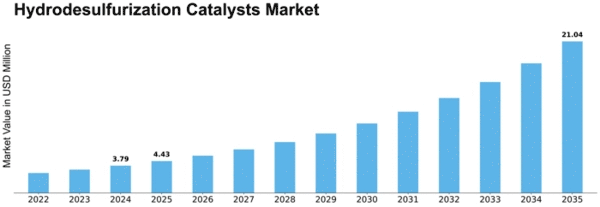

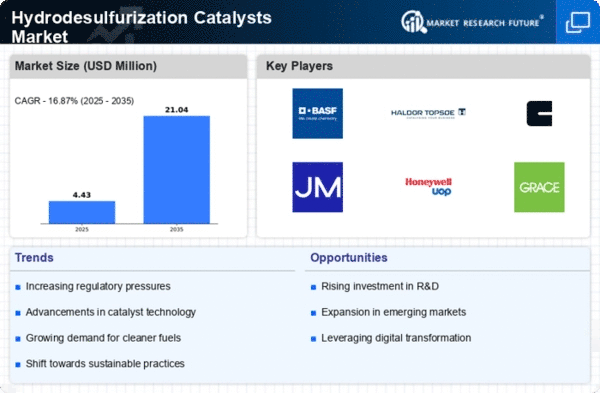

Hydrodesulfurization Catalysts Size

Hydrodesulfurization Catalysts Market Growth Projections and Opportunities

The hydrodesulfurization (HDS) catalysts market is influenced by several key factors that shape its dynamics and growth trajectory. One of the primary market factors is the increasing demand for cleaner fuels with reduced sulfur content. Hydrodesulfurization is a crucial process in the petroleum refining industry, where sulfur compounds are removed from crude oil and petroleum products to comply with environmental regulations and improve fuel quality. As governments worldwide implement stricter emission standards to reduce air pollution and mitigate environmental impacts, the demand for HDS catalysts to produce low-sulfur fuels continues to grow, driving market expansion.

Hydrodesulfurization, one of the most important processes in the oil refining industry, is a catalytic chemical process used to reduce pollutants in the fraction of petroleum distillates. It is widely used to remove sulfurfrom natural gas and refined petroleum products such as gasoline, diesel fuel, jet fuel, kerosene, and fuel oils. The catalysts used in this process are Hydrodesulfurization Catalysts Market. Crude oil contains a complex mixture of sulfur compounds, such as sulfides, disulfides, and thiols.

Moreover, technological advancements and innovations in catalyst formulations and manufacturing processes contribute to market growth. Continuous research and development efforts by catalyst manufacturers focus on improving the activity, selectivity, and stability of HDS catalysts to enhance their performance in sulfur removal processes. Additionally, advancements in catalyst support materials, promoters, and active metal components optimize the efficiency and effectiveness of HDS reactions, enabling refineries to meet stringent sulfur content specifications while minimizing catalyst consumption and operational costs.

Market factors also include changes in crude oil composition and sulfur content. With the depletion of conventional crude oil reserves and the increasing production of unconventional oil sources such as shale oil and bitumen, the sulfur content of crude oil varies widely depending on the source. As refiners process a diverse range of crude oils with varying sulfur content, the demand for flexible and efficient HDS catalysts capable of treating different feedstocks increases. Moreover, fluctuations in crude oil prices and availability impact refinery operations and investment decisions, influencing the demand for HDS catalysts in the petroleum refining industry.

Furthermore, regulatory standards and compliance requirements drive market demand for HDS catalysts. Government regulations and environmental mandates impose strict limits on sulfur emissions from transportation fuels, requiring refineries to invest in HDS technology and catalysts to meet regulatory compliance. Compliance with these regulations is essential for refineries to maintain their operating licenses and market competitiveness, driving continuous investment in HDS catalysts and sulfur removal technologies.

Additionally, macroeconomic factors such as economic growth and industrial activity influence the demand for refined petroleum products and, consequently, HDS catalysts. Economic expansion leads to increased demand for transportation fuels such as gasoline and diesel, driving refinery throughput and investment in upgrading and expansion projects. Moreover, industrialization and urbanization in emerging economies contribute to rising energy consumption and demand for cleaner fuels, supporting market growth for HDS catalysts in regions with growing refining capacity.

Global market trends and trade dynamics also impact the HDS catalysts market. International trade agreements, tariffs, and trade barriers affect the import and export of catalyst materials and finished products, influencing pricing dynamics and market competitiveness in different geographic regions. Moreover, shifts in global energy consumption patterns, technological advancements in refining processes, and geopolitical factors such as geopolitical tensions and supply disruptions in oil-producing regions influence the demand for HDS catalysts in the global petroleum refining industry.

Leave a Comment