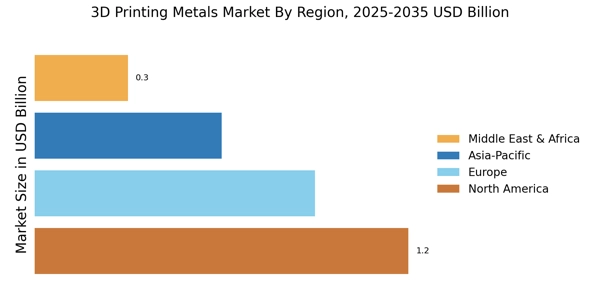

By region, the study provides market insights into North America, Europe, Asia-Pacific, and the Rest of the World. The Asia-Pacific region is expected to lead the global market for 3D printing metals in the coming years, driven by factors such as increasing industrialization, rising demand for 3D printing metals from various end-use industries, and supportive government initiatives. Countries such as China, Japan, and South Korea have been at the forefront of adopting 3D printing technology, and they are likely to continue to be major contributors to the growth of the 3D printing metals market in the region.

These countries have large manufacturing industries and are investing heavily in research and development to advance their capabilities in 3D printing. In addition, the healthcare industry in the Asia-Pacific region is also expected to be a major driver of growth in the 3D printing metals market. The region has a large population, and there is a growing demand for customized medical implants and prosthetics. 3D printing metals offer the ability to produce these products with greater precision and customization, leading to better patient outcomes.

Further, the major countries studied in the market report are The U.S., Canada, Germany, France, the UK, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil

Europe’s 3D Printing Metals market accounts for the third-largest market share. The region has a well-established manufacturing industry, with several leading companies in the aerospace, automotive, and healthcare sectors. The aerospace industry, in particular, has been a major driver of growth in the 3D printing metals market in Europe, with several companies using the technology to produce lightweight and complex components for aircraft. In addition, the European Union has been investing heavily in research and development in the 3D printing industry, with several initiatives aimed at advancing the technology and promoting its adoption in various industries.

The region has also been at the forefront of developing new 3D printing materials and techniques, which has helped to drive innovation in the industry. Further, the Germany 3D Printing Metals market held the largest market share, and the UK 3D Printing Metals market was the fastest-growing market in the European region.

North America, 3D Printing Metals market, is expected to grow at the fastest CAGR from 2023 to 2030. The region has a strong aerospace and defense industry, which has been a major driver of growth in the 3D printing metals market. In addition, the healthcare and automotive industries in North America have also shown significant potential for growth in the use of 3D printing metals. Moreover, the U.S. 3D Printing Metals market held the largest market share, and the Canada 3D Printing Metals market was the fastest-growing market in the North American region.