Growth in Food and Beverage Sector

The food and beverage sector in the United States is a major driver for the US Washdown Sensor Market. With the industry's continuous expansion, there is an increasing need for reliable and efficient washdown sensors to maintain hygiene and safety standards. The sector is projected to reach a market size of over 1 trillion dollars by 2026, which underscores the potential for growth in related industries, including washdown sensors. As food manufacturers seek to enhance their production processes and comply with health regulations, the demand for advanced washdown sensors is expected to rise. This growth trajectory indicates a robust opportunity for stakeholders within the US Washdown Sensor Market to capitalize on the increasing investments in food safety technologies.

Rising Automation in Manufacturing

The trend towards automation in manufacturing processes is significantly impacting the US Washdown Sensor Market. As companies strive for greater efficiency and productivity, the integration of automated systems necessitates the use of reliable washdown sensors. These sensors play a crucial role in ensuring that automated equipment remains clean and operational, thereby reducing downtime and maintenance costs. The manufacturing sector is increasingly adopting Industry 4.0 principles, which emphasize smart manufacturing and interconnected systems. This shift is likely to drive the demand for washdown sensors that can seamlessly integrate with existing automation technologies. Consequently, the US Washdown Sensor Market is poised for growth as manufacturers prioritize automation and seek to enhance their operational capabilities.

Increased Demand for Hygiene Standards

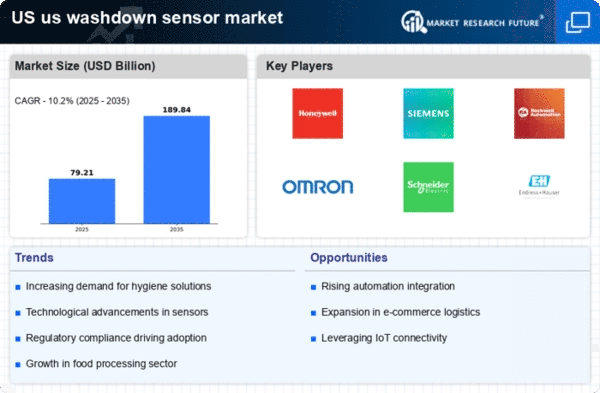

The US Washdown Sensor Market is experiencing heightened demand for hygiene standards across various sectors, particularly in food and beverage processing. Regulatory bodies, such as the FDA, have established stringent guidelines that necessitate the use of washdown sensors to ensure cleanliness and prevent contamination. This trend is likely to drive market growth, as companies invest in advanced sensor technologies to comply with these regulations. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years, reflecting the increasing emphasis on hygiene and safety in production environments. As industries prioritize sanitation, the adoption of washdown sensors becomes essential, thereby propelling the US Washdown Sensor Market forward.

Technological Innovations in Sensor Design

Technological advancements in sensor design are significantly influencing the US Washdown Sensor Market. Innovations such as improved materials that withstand harsh cleaning processes and enhanced sensitivity to detect contaminants are becoming prevalent. For instance, sensors that utilize advanced materials like stainless steel and specialized coatings are gaining traction due to their durability and effectiveness in washdown applications. The integration of IoT capabilities into washdown sensors is also emerging, allowing for real-time monitoring and data collection. This evolution in technology not only enhances operational efficiency but also aligns with the growing trend of automation in manufacturing. As a result, the US Washdown Sensor Market is likely to see an influx of new products that cater to these technological demands.

Focus on Sustainability and Environmental Compliance

Sustainability and environmental compliance are becoming pivotal considerations within the US Washdown Sensor Market. As companies face increasing pressure to adopt eco-friendly practices, the demand for washdown sensors that minimize water and energy consumption is on the rise. Regulatory frameworks are evolving to promote sustainable manufacturing processes, which further drives the need for sensors that align with these initiatives. For instance, sensors that optimize cleaning processes can significantly reduce water usage, thereby contributing to environmental conservation efforts. This focus on sustainability not only enhances corporate responsibility but also positions companies favorably in the eyes of consumers. As a result, the US Washdown Sensor Market is likely to witness a shift towards more sustainable sensor solutions that meet both regulatory and consumer expectations.