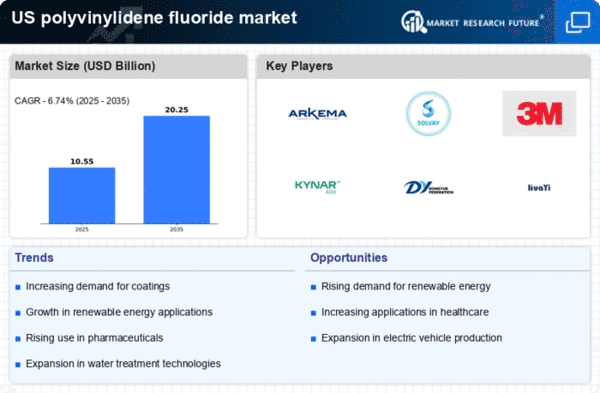

The polyvinylidene fluoride market is currently characterized by a competitive landscape that is both dynamic and multifaceted. Key growth drivers include the increasing demand for high-performance materials in industries such as automotive, electronics, and renewable energy. Major players such as Arkema (FR), Solvay (BE), and 3M (US) are strategically positioned to leverage innovation and technological advancements. Arkema (FR) focuses on expanding its product portfolio through research and development, while Solvay (BE) emphasizes sustainability in its operations. 3M (US) is known for its strong emphasis on digital transformation and customer-centric solutions, which collectively shape a competitive environment that is increasingly reliant on innovation and sustainability.In terms of business tactics, companies are localizing manufacturing to enhance supply chain efficiency and reduce lead times. The market structure appears moderately fragmented, with several key players exerting influence over pricing and product availability. This fragmentation allows for niche players to thrive, while larger corporations optimize their operations to maintain competitive advantages. The collective influence of these key players fosters a competitive atmosphere where agility and responsiveness to market demands are paramount.

In October Arkema (FR) announced the launch of a new line of polyvinylidene fluoride products aimed at the renewable energy sector. This strategic move is significant as it aligns with global trends towards sustainability and clean energy solutions, positioning Arkema as a leader in providing materials that support the transition to greener technologies. The introduction of these products is likely to enhance Arkema's market share and reinforce its commitment to innovation.

In September Solvay (BE) entered into a partnership with a leading automotive manufacturer to develop advanced polyvinylidene fluoride coatings. This collaboration is indicative of Solvay's strategy to integrate sustainability into its product offerings, as these coatings are designed to improve energy efficiency in vehicles. Such partnerships not only enhance Solvay's product portfolio but also strengthen its position in the automotive sector, which is increasingly focused on reducing environmental impact.

In August 3M (US) unveiled a new digital platform aimed at optimizing the supply chain for its polyvinylidene fluoride products. This initiative reflects 3M's commitment to digital transformation and operational efficiency. By leveraging advanced analytics and AI, 3M aims to enhance customer experience and streamline its operations, which could lead to improved market responsiveness and customer satisfaction.

As of November current competitive trends in the polyvinylidene fluoride market are heavily influenced by digitalization, sustainability, and the integration of AI technologies. Strategic alliances are becoming increasingly important, as companies seek to enhance their capabilities and market reach. The competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability. This shift suggests that companies that prioritize these aspects will be better positioned to thrive in an ever-evolving market landscape.