Market Analysis

In-depth Analysis of US Green Steel Market Industry Landscape

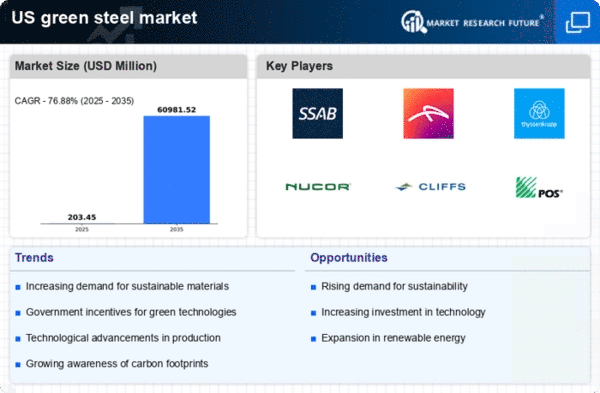

The US green steel market is undergoing dynamic changes, shaped by a convergence of factors that influence the production, demand, and sustainability aspects of the steel industry. Green steel, also known as low-carbon or sustainable steel, is produced using environmentally friendly processes with reduced carbon emissions. The market dynamics are characterized by technological advancements, environmental regulations, growing emphasis on sustainability, and the transformation of the traditional steelmaking landscape.

Technological advancements are a driving force behind the dynamic nature of the US green steel market. Innovations in steelmaking processes, such as hydrogen-based direct reduction and electric arc furnaces powered by renewable energy sources, are reshaping the industry. These advancements aim to reduce or eliminate carbon emissions associated with traditional steel production methods, aligning with the broader goal of achieving a low-carbon and sustainable steel sector. As these technologies mature, their adoption is expected to impact the competitiveness and market share of green steel.

Environmental regulations play a crucial role in shaping the market dynamics of green steel in the US. With a growing focus on mitigating climate change and reducing greenhouse gas emissions, regulatory standards and carbon pricing mechanisms are impacting the steel industry. Emission reduction targets and mandates may drive steel producers to adopt greener technologies and invest in sustainable practices to comply with environmental regulations. This regulatory landscape influences the overall trajectory of the green steel market, encouraging the transition towards more sustainable steel production methods.

The growing emphasis on sustainability is a key driver shaping the market dynamics of green steel. Consumers, industries, and governments are increasingly prioritizing products with lower environmental footprints, including steel. The demand for green steel is driven by the desire to minimize the environmental impact of steel production, from raw material extraction to manufacturing processes. Sustainability certifications and eco-labels may become influential factors in consumer and industry preferences, influencing the market dynamics of green steel products.

The transformation of the traditional steelmaking landscape is a notable factor in the dynamic nature of the US green steel market. Traditional steel production, based on blast furnace technology, is being challenged by alternative methods that offer reduced carbon emissions. Green steel technologies, such as direct reduced iron (DRI) and hydrogen-based steelmaking, are gaining traction as viable alternatives. This transformation reflects the industry's response to the imperative of reducing carbon intensity and aligning with global sustainability goals.

Competition within the market fosters innovation and efficiency in green steel production. Companies are continually striving to differentiate themselves by offering high-quality green steel products, exploring new technologies, and optimizing production processes. Collaborations and partnerships between steel producers, technology providers, and research institutions are driving innovation within the green steel industry, influencing the competitive landscape and shaping market dynamics.

Socio-economic factors, including economic trends, consumer preferences, and infrastructure development, contribute to the market dynamics of green steel in the US. Economic growth often correlates with increased demand for steel in construction, infrastructure projects, and manufacturing. As sustainability becomes a more significant factor in purchasing decisions, the demand for green steel may see growth in response to evolving consumer preferences and corporate sustainability goals.

Leave a Comment