Rising Demand for Aesthetic Solutions

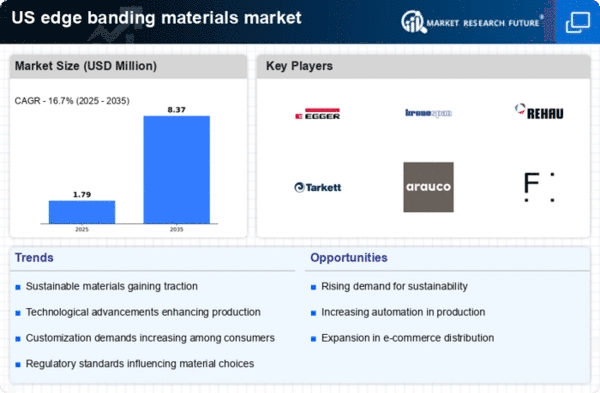

The edge banding-materials market is experiencing a notable increase in demand driven by the growing consumer preference for aesthetically pleasing furniture and cabinetry. As homeowners and designers seek to enhance the visual appeal of their interiors, the use of edge banding materials becomes essential. This trend is particularly evident in the residential sector, where the market for decorative edge banding is projected to grow at a CAGR of approximately 6% over the next five years. The edge banding-materials market is thus positioned to benefit from this shift towards more visually appealing products, as manufacturers innovate to provide a variety of colors, textures, and finishes that cater to diverse design preferences.

Regulatory Support for Sustainable Practices

The edge banding-materials market is influenced by regulatory support for sustainable practices within the manufacturing sector. As environmental concerns gain prominence, regulations encouraging the use of eco-friendly materials are becoming more prevalent. This shift is prompting manufacturers to explore sustainable options for edge banding materials, such as those made from recycled or renewable resources. The edge banding-materials market is likely to benefit from this trend, as consumers increasingly prefer products that align with their values regarding sustainability. Companies that adapt to these regulations and invest in sustainable practices may find themselves at a competitive advantage in the evolving market landscape.

Growth in DIY and Home Improvement Activities

The edge banding-materials market is benefiting from the rising trend of DIY (do-it-yourself) and home improvement activities among consumers. As more individuals engage in home renovation projects, the demand for edge banding materials is expected to increase. This trend is particularly pronounced among millennials and Gen Z homeowners, who are increasingly inclined to personalize their living spaces. The edge banding-materials market is likely to see a surge in sales as these consumers seek out materials that allow for customization and creativity in their projects. Retailers are responding by expanding their offerings of edge banding products, catering to this growing segment of the market.

Expansion of the Furniture Manufacturing Sector

The edge banding-materials market is significantly influenced by the expansion of the furniture manufacturing sector in the United States. As the industry continues to grow, driven by increased consumer spending on home furnishings, the demand for edge banding materials is expected to rise correspondingly. In 2025, the furniture manufacturing sector is projected to reach a market value of over $100 billion, creating substantial opportunities for edge banding suppliers. This growth is likely to be fueled by both residential and commercial projects, where the need for durable and aesthetically pleasing finishes is paramount. Consequently, the edge banding-materials market stands to gain from this robust growth trajectory.

Technological Innovations in Manufacturing Processes

Technological advancements in manufacturing processes are playing a crucial role in shaping the edge banding-materials market. Innovations such as automated edge banding machines and advanced adhesive technologies are enhancing production efficiency and product quality. These developments enable manufacturers to produce edge banding materials that are not only more durable but also offer improved adhesion and finish. As a result, the edge banding-materials market is likely to witness increased adoption of these technologies, which could lead to a reduction in production costs and an expansion of product offerings. This trend may also attract new entrants into the market, further stimulating competition and innovation.