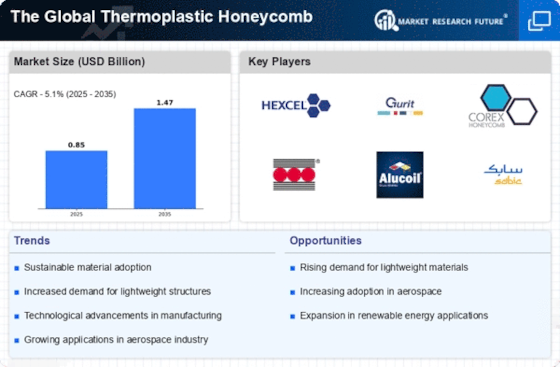

Market Trends

Key Emerging Trends in the Thermoplastic Honeycomb Market

The current Thermoplastic Honeycomb Market is characterized by significant trends that depict a dynamic landscape of aerospace, automotive, and construction industries. Lightweight hexagonal patterned thermoplastic honeycomb structures made from strong materials have undergone notable shifts in demand across various sectors because they have become lighter cars or planes, thus influencing their choice. One of these trends entails increased usage of thermoplastic honeycombs in aerospace, particularly for aircraft interiors, among other parts. Moreover, there has been an upsurge in demand for thermoplastic honeycombs within the automobile sector. These materials are used in different vehicle parts, including interior panels, body panels, plus seating arrangements, to enhance weight saving, thereby increasing fuel efficiency. As the car industry focuses more on sustainability with electric vehicles taking shape, this has seen increased importance placed on thermoplastic honeycombs due to their ability to help achieve weight reduction targets; hence, it helps improve overall vehicle efficiency. Moreover, the Thermoplastic Honeycomb market features innovativeness in formulations, customizing them to particular industrial needs. Inventions directed at making tailored properties such as better thermal stability, fire resistance, or specific mechanical characteristics in thermo-plastic honeycombs have resulted from manufacturers' investments in this area. On the other hand, there has been greater emphasis on sustainability and safety within the aerospace, automotive, and construction sectors with respect to the utilization of materials like thermoplastic honeycombs. Manufacturers are adjusting their formulations to meet regulations regarding emissions, recycling, and overall environmental impact. This demonstrates that industries are increasingly adopting sustainable practices and responsible use of materials, which are in line with global efforts aimed at reducing manufacturing's carbon footprint. In addition, the market sees a growing need for thermoplastic honeycombs among emerging economies. In order to carry out various applications within the aerospace industry as well as the automobile or building sector, rapid industrialization and urbanization are taking place in Asia-Pacific countries, including the Philippines, resulting in demand for thermoplastic honeycombs. On the side of technological advancement, the Thermoplastic Honeycomb market is experiencing innovations in production methods so as to enhance efficiency while reducing environmental impacts. This entails the exploration of advanced manufacturing processes, sourcing raw materials sustainably, and the development of better-performing thermoplastic honeycombs, among others. This current trend is consistent with an overall industry focus on green technologies and sustainable practices when it comes to material production.

Leave a Comment