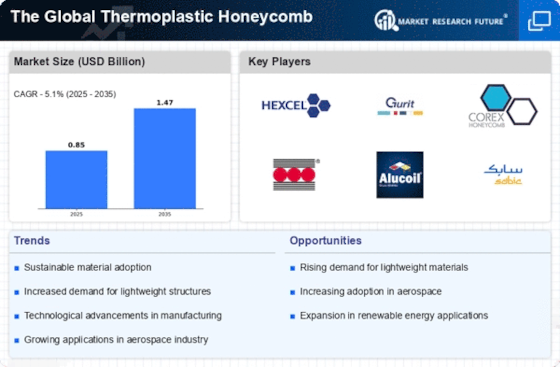

Market Analysis

In-depth Analysis of Thermoplastic Honeycomb Market Industry Landscape

Within materials and manufacturing sectors, Thermoplastic Honeycomb's market dynamics are critical, outlining different factors that influence trends within its production demand, among other overall market aspects. There is a broad range of applications for thermoplastics that have honeycomb structures where hexagonal cells are found in aerospace, automobile engineering, and construction due to their lightweight, high tensile strength, and energy-absorbing properties. As an example, global supply chain fluctuations affect the thermoplastic honeycomb, including economic cycles in both domestic economies and international environments, which actually determine how much the economy will require such structures in different industries. On the other hand, economic growth tends to increase its usage in different applications. However, a recession implies that manufacturing activities decline, resulting in lower use of thermoplastic honeycomb. Therefore, the market is vulnerable and dependent on global economic indicators that affect all investment decisions made by producers, as well as their pricing strategies and output levels. Environmental concerns increasingly influence the dynamics of the Thermoplastic Honeycomb market. As a result of growing concern for sustainability and eco-friendly practices, demand for honeycomb structures with low environmental footprints is on the increase. In this field, market competition is very intense due to the nature of these kinds of structures. Manufacturers should focus on product quality, being cost-effective in their products, and innovation so as to differentiate themselves from competitors. For instance, special formulations can be developed for specific applications or improved performance characteristics, which are some common differentiation strategies used in acquiring market shares by manufacturers dealing with this unique type of complex honeycombs. Companies must keep current and outpace the competition by continuously researching since customers' needs always change over time. Trade policies and geopolitical factors play a role in the overall market dynamics of thermoplastic honeycombs. Given that aerospace and automotive manufacturing is done globally, tariffs, import/export regulations, and geopolitical tensions can impact the global supply chain, leading to the availability and prices of thermoplastic honeycomb structures being different across regions. Regulations and standards also shape the Thermoplastic Honeycomb Market. In order to penetrate the market, there must be compliance with safety standards, quality regulations, and industry-specific requirements. Consumer preferences and market trends also influence the dynamics of the Thermoplastic Honeycomb market. Changes in consumer preferences, such as demand for fuel-efficient aircraft components, lightweight automotive structures, and sustainable building materials, greatly influence the decision on which thermoplastic honeycomb structure to go for.

Leave a Comment