Cost Efficiency

Cost efficiency remains a critical driver in the Thermoformed Plastics For Printing Market. As competition intensifies, manufacturers are compelled to optimize their production processes to reduce costs while maintaining quality. Innovations in materials and manufacturing techniques contribute to lower production expenses, enabling companies to offer competitive pricing. Additionally, the ability to produce lightweight and durable thermoformed products can lead to savings in transportation and logistics. This focus on cost efficiency is essential for companies aiming to enhance profitability and market presence, particularly in price-sensitive segments of the industry.

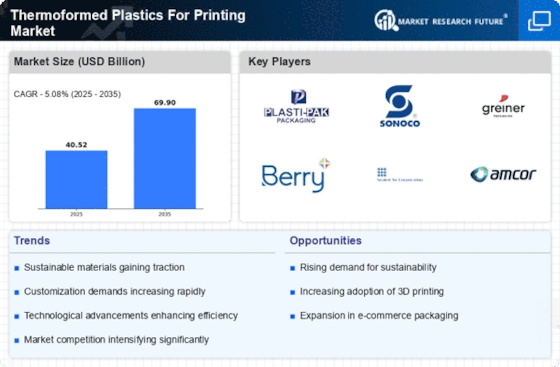

Customization Demand

The rising demand for customization within the Thermoformed Plastics For Printing Market is reshaping product offerings. Consumers increasingly seek personalized solutions that cater to their specific needs, prompting manufacturers to adapt their production strategies. This trend is particularly evident in sectors such as packaging, where tailored designs can enhance brand identity and consumer engagement. The ability to offer customized thermoformed products not only meets consumer expectations but also fosters brand loyalty. As businesses recognize the value of personalization, investments in flexible manufacturing processes are likely to increase, further driving growth in the market.

Regulatory Compliance

Regulatory compliance is increasingly influencing the Thermoformed Plastics For Printing Market. Governments worldwide are implementing stricter regulations regarding plastic usage and waste management, prompting manufacturers to adapt their practices. Compliance with these regulations not only mitigates legal risks but also aligns with consumer expectations for responsible production. Companies that proactively address regulatory requirements may find new opportunities for growth, particularly in markets that prioritize sustainability. As the regulatory landscape evolves, businesses that invest in compliant and innovative thermoformed solutions are likely to thrive in an increasingly competitive environment.

Technological Innovations

Technological advancements play a pivotal role in shaping the Thermoformed Plastics For Printing Market. Innovations in manufacturing processes, such as 3D printing and advanced molding techniques, enhance the efficiency and quality of thermoformed products. These technologies enable the production of complex designs and customized solutions, catering to diverse consumer needs. Furthermore, the integration of automation and smart technologies in production lines is likely to reduce costs and improve turnaround times. As a result, companies that leverage these technological innovations may experience increased market share and profitability, positioning themselves favorably in a competitive landscape.

Sustainability Initiatives

The increasing emphasis on sustainability within the Thermoformed Plastics For Printing Market is driving demand for eco-friendly materials. Manufacturers are increasingly adopting biodegradable and recyclable plastics, aligning with consumer preferences for environmentally responsible products. This shift not only meets regulatory requirements but also enhances brand reputation. As a result, companies that prioritize sustainable practices are likely to gain a competitive edge. The market for sustainable thermoformed plastics is projected to grow, reflecting a broader trend towards reducing environmental impact. This focus on sustainability is expected to influence purchasing decisions, as consumers become more aware of the ecological footprint of their choices.