Consumer Preferences

Consumer preferences are evolving, significantly impacting the Heavy Gauge and Thin Gauge Thermoformed Plastic Market. There is a noticeable shift towards convenience and functionality in product design, with consumers favoring packaging solutions that enhance usability. This trend is particularly evident in the food and beverage sector, where easy-to-open and resealable packaging is gaining popularity. Additionally, consumers are increasingly aware of the environmental impact of their choices, leading to a demand for sustainable packaging options. In 2025, it is anticipated that brands that align their offerings with these preferences will experience enhanced customer loyalty and market share. Understanding and adapting to these changing consumer preferences is crucial for companies aiming to thrive in the competitive thermoformed plastic landscape.

Diverse Applications

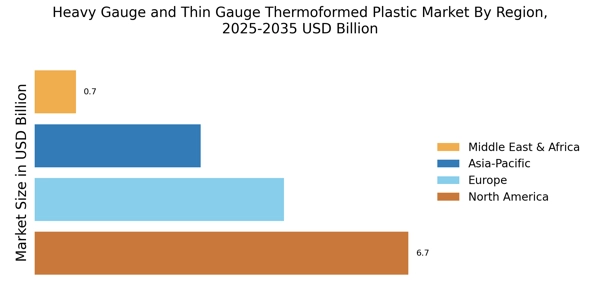

The Heavy Gauge and Thin Gauge Thermoformed Plastic Market is characterized by its diverse applications across various sectors. Industries such as food packaging, automotive, and healthcare are increasingly utilizing thermoformed plastics due to their versatility and cost-effectiveness. In the food packaging sector, for instance, thermoformed trays and containers are favored for their ability to preserve freshness and extend shelf life. The automotive industry is also adopting these materials for lightweight components, contributing to fuel efficiency. In 2025, the demand for thermoformed plastics in healthcare is projected to rise, driven by the need for sterile packaging solutions. This broad range of applications suggests a robust market potential, as different sectors continue to explore the benefits of thermoformed plastics.

Regulatory Compliance

Regulatory compliance is a significant driver in the Heavy Gauge and Thin Gauge Thermoformed Plastic Market. Governments worldwide are implementing stringent regulations regarding plastic usage, recycling, and waste management. These regulations compel manufacturers to adapt their practices to meet compliance standards, which can lead to increased operational costs. However, companies that proactively embrace these regulations may find opportunities for innovation and market differentiation. In 2025, the emphasis on compliance is expected to intensify, particularly in regions with strict environmental policies. This trend may drive investments in research and development to create compliant products that meet both regulatory requirements and consumer expectations, ultimately shaping the future landscape of the thermoformed plastic market.

Sustainability Initiatives

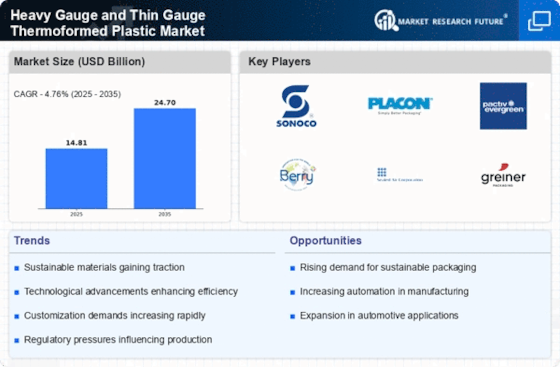

The Heavy Gauge and Thin Gauge Thermoformed Plastic Market is increasingly influenced by sustainability initiatives. As environmental concerns rise, manufacturers are adopting eco-friendly practices, including the use of recyclable materials and energy-efficient production processes. This shift not only meets regulatory requirements but also aligns with consumer preferences for sustainable products. The market is witnessing a growing demand for biodegradable and recyclable thermoformed plastics, which are perceived as more environmentally responsible. In 2025, the market for sustainable packaging solutions is projected to reach substantial figures, indicating a robust growth trajectory. Companies that prioritize sustainability are likely to gain a competitive edge, as consumers increasingly favor brands that demonstrate environmental stewardship.

Technological Advancements

Technological advancements play a pivotal role in shaping the Heavy Gauge and Thin Gauge Thermoformed Plastic Market. Innovations in manufacturing processes, such as improved thermoforming techniques and automation, enhance production efficiency and product quality. The integration of advanced materials, including high-performance polymers, allows for the creation of lighter and more durable products. In 2025, the market is expected to benefit from the introduction of smart manufacturing technologies, which could streamline operations and reduce waste. Furthermore, advancements in design software enable more complex and customized product designs, catering to diverse consumer needs. As technology continues to evolve, it is likely to drive significant growth in the thermoformed plastic sector.