Growing Aerospace Industry

The aerospace industry is emerging as a vital driver for the stainless steel forging market, with increasing demand for high-performance materials in aircraft manufacturing. Stainless steel components are favored for their strength-to-weight ratio and resistance to extreme temperatures, making them essential for various aircraft parts. In 2025, the aerospace sector is projected to witness substantial growth, with a focus on developing more fuel-efficient and environmentally friendly aircraft. This trend is likely to result in heightened demand for stainless steel forged components, as manufacturers seek materials that can withstand rigorous operational conditions. The stainless steel forging market stands to benefit from this growth, as aerospace companies increasingly rely on advanced forging techniques to produce critical components that meet stringent safety and performance standards.

Rising Demand in Automotive Sector

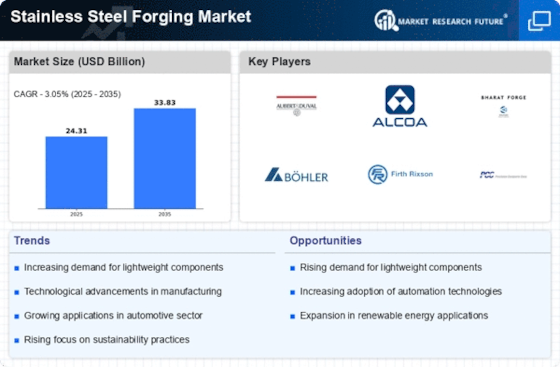

The automotive sector is experiencing a notable surge in demand for stainless steel forging components, driven by the industry's shift towards lightweight materials and enhanced durability. Stainless steel forging market is poised to benefit from this trend, as manufacturers increasingly seek high-strength, corrosion-resistant materials for vehicle parts. In 2025, the automotive industry is projected to account for a significant share of the stainless steel forging market, with estimates suggesting a growth rate of approximately 5% annually. This demand is further fueled by the increasing production of electric vehicles, which require advanced materials to meet performance and safety standards. As automakers prioritize sustainability and efficiency, the stainless steel forging market is likely to see a corresponding rise in orders for forged components, thereby solidifying its position within the automotive supply chain.

Infrastructure Development Projects

Infrastructure development projects are a critical driver for the stainless steel forging market, as governments and private entities invest heavily in construction and renovation initiatives. The demand for robust and durable materials in infrastructure applications, such as bridges, buildings, and pipelines, is expected to escalate. In 2025, the global infrastructure spending is projected to reach trillions of dollars, with a substantial portion allocated to projects requiring stainless steel forged components. The inherent properties of stainless steel, including its strength and resistance to corrosion, make it an ideal choice for these applications. Consequently, the stainless steel forging market is likely to experience increased orders from construction firms and infrastructure developers, further enhancing its growth trajectory in the coming years.

Expansion of Renewable Energy Sector

The expansion of the renewable energy sector is significantly influencing the stainless steel forging market, as the demand for durable and corrosion-resistant materials increases. Wind turbines, solar panels, and other renewable energy technologies require high-quality stainless steel components to ensure longevity and efficiency. In 2025, investments in renewable energy are expected to reach unprecedented levels, with a focus on sustainable solutions to combat climate change. This trend is likely to drive the demand for stainless steel forged products, as manufacturers seek reliable materials for energy infrastructure. The stainless steel forging market is well-positioned to capitalize on this growth, as the properties of stainless steel align with the requirements of renewable energy applications, thereby fostering a robust market environment.

Technological Innovations in Forging Processes

Technological innovations in forging processes are transforming the stainless steel forging market, leading to enhanced efficiency and product quality. Advanced techniques such as precision forging and computer numerical control (CNC) machining are being adopted to produce complex shapes and tighter tolerances. These innovations not only reduce material waste but also improve the overall performance of forged components. In 2025, the market is expected to witness a rise in the adoption of these technologies, as manufacturers strive to meet the growing demands for high-performance stainless steel products. The integration of automation and robotics in forging processes is likely to further streamline production, thereby increasing the competitiveness of the stainless steel forging market. As a result, companies that invest in these technological advancements may gain a significant edge in the marketplace.