Top Industry Leaders in the Process Automation Instrumentation Market

The Competitive Landscape of the Process Automation Instrumentation Market

The process automation instrumentation market, once a quiet hum in the background of industrial operations, has burst onto the center stage of economic growth. These sensors, valves, controllers, and software conductors orchestrate the complex dance of materials, chemicals, and energy flows in diverse industries, from oil and gas refineries to food and beverage plants. Understanding the intricacies of this dynamic market, analyzing key players' strategies, and identifying emerging trends is crucial for navigating the landscape and seizing opportunities.

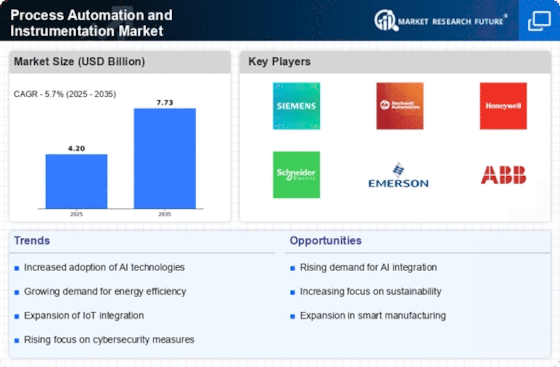

Some of the Process Automation and Instrumentation companies listed below:

- ABB Ltd

- General Electric Co.

- Mitsubishi Electric Corporation

- Rockwell Automation Inc.

- Emerson Electric Co.

- Siemens AG

- Yokogawa Electric Corporation

- Metso Corporation

- Schnieder Electric SE

Strategies Adopted by Leaders:

- Embracing Innovation and Next-Generation Technologies: Investing in R&D to integrate advancements like artificial intelligence (AI) for predictive maintenance, cloud-based data analytics for real-time insights, and digital twins for process simulation differentiates solutions and caters to evolving industry needs.

- Prioritizing User Experience and Ease of Use: Providing intuitive interfaces, user-friendly software, and ergonomic equipment simplifies operation and minimizes training requirements, particularly for non-technical personnel.

- Partnerships and Ecosystem Building: Collaborating with equipment manufacturers, system integrators, software developers, and industry associations expands reach, offers complete solutions, and strengthens brand presence.

- Focus on Scalability and Modular Design: Developing modular systems and scalable solutions allows for flexible adaptations to evolving process requirements and plant expansions, providing long-term value to customers.

- Sustainability and Environmental Considerations: Utilizing energy-efficient sensors, offering low-emission equipment, and minimizing waste in production processes cater to customers with growing sustainability concerns and compliance regulations.

Factors for Market Share Analysis:

- Product Portfolio and Technological Breadth: The range and sophistication of instruments offered, encompassing diverse sensor types like pressure, temperature, flow, and level, with varying accuracy, communication protocols, and integration capabilities, significantly impact market reach. Catering to specific applications, such as high-temperature environments or corrosive chemicals, can be significant differentiators.

- Target Market Focus: Focusing on specific segments within the industrial ecosystem, such as chemical processing, oil and gas exploration, power generation, or water treatment, requires tailored solutions and partnership strategies. Addressing the unique needs of each segment can solidify market share within that niche.

- Software and System Integration: Providing robust software platforms for data acquisition, process monitoring, optimization algorithms, and seamless integration with enterprise resource planning (ERP) systems enables efficient decision-making and improves operational efficiency.

- Security and Data Privacy: Implementing robust cybersecurity protocols, adhering to data privacy regulations, and ensuring secure data communication are paramount for protecting sensitive industrial information and building trust with customers.

- Service and Support Packages: Offering comprehensive installation, maintenance, calibration, and training services enhances customer experience and ensures optimal instrument performance throughout their lifecycle.

New and Emerging Companies:

- Niche-Focused Startups: Companies like Endress+Hauser and Yokogawa Electric specialize in developing sensors and solutions for specific applications like cryogenic environments or biopharmaceutical processes, offering unparalleled performance and expertise in demanding environments.

- Software-Centric Platforms: Companies like GE Digital and Aspen Technology focus on developing advanced software platforms that optimize control strategies, provide real-time data visualizations, and enable AI-powered process optimization, adding significant value beyond the hardware itself.

- Open-Source Hardware Advocates: Companies like Arduino and BeagleBone offer open-source hardware platforms for industrial sensors and controllers, empowering researchers and DIY enthusiasts with customization options and fostering innovation within the community.

Latest Company Updates:

Nov. 13, 2023, The Advantage Travel Partnership, a pre-eminent business network representing travel agents and travel management companies in the UK, announced a collaboration with Lokulus, a business process automation platform provider, to enable TMCs to streamline operations and reduce response times.

Nov. 08, 2023, ConnectWise, a leading global software company, showcased the evolution and future of its Asio Platform at IT Nation Connect. ConnectWise RPA is now available in the ConnectWise Asio Platform to help TSPs overcome client challenges while reducing labor costs.

Oct.26, 2023, DGTAL, a SaaS platform providing AI-powered audits and tools for insurance portfolios, launched a new intelligent document processing tool, GRABBER. The new AI data capturing & process automation tool can understand, extract, and validate data from sources such as bank statements, invoices, utility bills, quotes & order forms, etc. GRABBER uses the most innovative approaches in optical character recognition (OCR), NLP, ML, and AI.

Aug. 29, 2023, Flojoy, an early-stage startup, announced a no-code Python testing to industrial instrumentation to help with a new open-source tool that lets companies build test scripts in an automated way. The company also announced a $1.3 million seed round to build out the vision and its plan to release its open-source software. The company is focused on this particular niche of test measurement and control, equivalent to software testing in the technology industry.

Apr.04, 2023, Siemens Egypt signed a training agreement with Techno Meter Group for process instrumentation. At TMG's training center, Siemens will support TMG in capacity-building to improve human specialized skills. This agreement aligns with Egypt's strategic plan to improve its water supply to serve a more sustainable water domain. Under this agreement, Siemens will share its capacity and caliber building expertise in the process instrumentation field to educate and qualify TMG's technical staff to enable them to achieve optimal operational performance.