Market Analysis

In-depth Analysis of Polyolefin Fiber Market Industry Landscape

The polyolefin fiber market is driven by various market dynamics that influence its growth and development. Polyolefin fibers, including polyethylene (PE) and polypropylene (PP), are synthetic fibers derived from polymers and are widely used in various applications due to their advantageous properties such as durability, strength, lightweight, and resistance to chemicals and moisture.

Escalating demand for nonwoven fabrics from the textile industry as a result of superior properties such as flame retardant, resilience and softness are boosting the market growth

One of the key market dynamics driving the polyolefin fiber market is the increasing demand from various end-use industries such as textiles, automotive, construction, and packaging. The versatility of polyolefin fibers makes them suitable for a wide range of applications, leading to their growing adoption across different sectors. In the textile industry, polyolefin fibers are used in the production of clothing, home textiles, and industrial textiles due to their comfort, softness, and easy care properties.

Another significant factor influencing the market dynamics of polyolefin fibers is the growing emphasis on sustainability and eco-friendly materials. Polyolefin fibers are recyclable and can be produced using environmentally friendly processes, making them a preferred choice for industries looking to reduce their carbon footprint and comply with stringent environmental regulations. As consumers become more conscious of the environmental impact of products, the demand for sustainable materials like polyolefin fibers is expected to increase further.

Additionally, technological advancements and innovations in the manufacturing processes of polyolefin fibers have contributed to market growth. Manufacturers are continuously investing in research and development to improve the properties and performance of polyolefin fibers, making them more suitable for specialized applications and expanding their market potential. For example, advancements in melt spinning technology have enabled the production of finer and more uniform polyolefin fibers with enhanced characteristics, opening up new opportunities in industries such as filtration, healthcare, and geotextiles.

The fluctuating prices of raw materials, particularly crude oil and natural gas, also play a significant role in shaping the market dynamics of polyolefin fibers. Since polyolefin fibers are derived from petrochemical feedstocks, their prices are closely linked to the volatility of oil and gas prices in the global market. Any fluctuations in raw material prices can impact the production costs of polyolefin fibers, thereby influencing their market dynamics and pricing strategies.

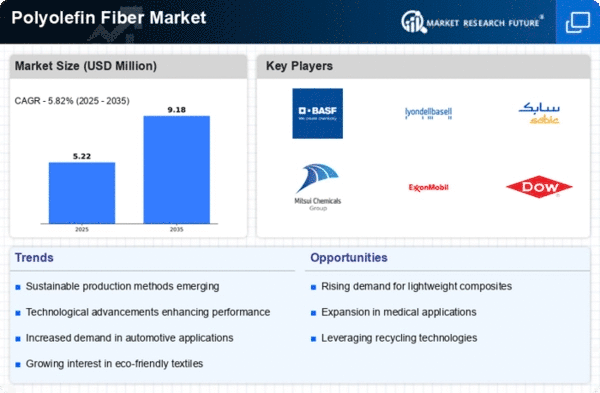

Moreover, the competitive landscape of the polyolefin fiber market is characterized by the presence of several key players competing for market share. These companies are constantly striving to differentiate their products through innovations, product enhancements, and strategic partnerships to gain a competitive edge in the market. Market consolidation through mergers and acquisitions is also a common trend observed in the polyolefin fiber industry, as companies seek to expand their market presence and diversify their product portfolios.

Furthermore, macroeconomic factors such as economic growth, industrialization, urbanization, and demographic trends also influence the demand for polyolefin fibers. Rapid urbanization and rising disposable incomes in emerging economies are driving the demand for textiles, automotive components, and packaging materials, thereby fueling the growth of the polyolefin fiber market in these regions.

Leave a Comment