Market Trends

Key Emerging Trends in the Methacrylate Monomers Market

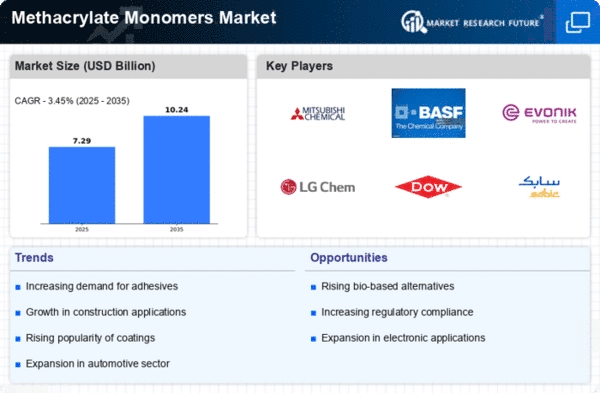

The methacrylate monomers market is experiencing significant trends that are shaping the industry and driving its growth trajectory. One prominent trend is the increasing demand for methacrylate monomers across various end-use industries such as automotive, construction, electronics, and healthcare. Methacrylate monomers are versatile chemicals used in the production of polymers, resins, coatings, adhesives, and sealants due to their excellent adhesive properties, chemical resistance, weatherability, and optical clarity. As industries seek high-performance materials for advanced applications, the demand for methacrylate monomers continues to rise, driving market expansion across diverse sectors.

Moreover, there is a growing emphasis on sustainability and environmental consciousness in the methacrylate monomers market, driven by increasing regulatory scrutiny and consumer awareness of environmental issues. Methacrylate monomers offer advantages such as low VOC emissions, recyclability, and compatibility with eco-friendly manufacturing processes, making them an attractive option for industries seeking to reduce their environmental footprint. Additionally, advancements in green chemistry and bio-based feedstocks are driving the development of sustainable methacrylate monomers derived from renewable resources such as plant oils, biomass, and recycled plastics. This trend towards sustainability aligns with the industry's commitment to environmental stewardship and circular economy principles.

Furthermore, the market is witnessing increasing demand for specialty methacrylate monomers with tailored properties and functionalities to meet specific application requirements. Manufacturers are investing in research and development to create advanced methacrylate monomers with improved performance characteristics such as enhanced adhesion, UV resistance, thermal stability, and impact resistance. Specialty methacrylate monomers are used in high-value applications such as automotive coatings, optical lenses, medical devices, and electronic components, where precise control over material properties is critical. As industries continue to innovate and develop new products, the demand for specialty methacrylate monomers is expected to grow, driving market expansion and fostering innovation in the industry.

Additionally, the market for methacrylate monomers is experiencing a shift towards digitalization and customization, driven by technological advancements and changing consumer preferences. With the rise of e-commerce, online customization tools, and digital manufacturing technologies, industries are increasingly seeking customized methacrylate monomers and formulations tailored to specific performance requirements, processing parameters, and aesthetic preferences. Additionally, digital tools such as computer-aided design (CAD), simulation software, and additive manufacturing are enabling rapid prototyping, product development, and customization of methacrylate-based materials. This trend towards digitalization and customization is driving investment in research and development, product innovation, and customer engagement strategies in the methacrylate monomers market.

Leave a Comment