Market Analysis

In-depth Analysis of Methacrylate Monomers Market Industry Landscape

The market dynamics of the methacrylate monomers industry are influenced by various factors that impact supply, demand, and pricing within the market. Methacrylate monomers serve as essential building blocks for various polymers and resins used in industries such as automotive, construction, electronics, and healthcare. One of the primary drivers of this market is the increasing demand for methacrylate-based polymers due to their versatility, durability, and performance characteristics. Methacrylate monomers are known for their excellent adhesion, weatherability, chemical resistance, and optical clarity, making them suitable for a wide range of applications. As industries continue to seek high-performance materials for advanced applications, there is a growing preference for methacrylate monomers, driving market growth in this segment.

Moreover, technological advancements in methacrylate monomer synthesis and polymerization processes play a significant role in shaping market dynamics. Manufacturers are constantly innovating to develop new monomer formulations with improved properties such as higher reactivity, lower viscosity, and enhanced compatibility with other materials. These advancements enable the development of customized polymers tailored to specific applications, driving demand for methacrylate monomers. As technology evolves and production costs decrease, the demand for methacrylate monomers is expected to increase, further propelling market expansion in this segment.

Furthermore, the diverse range of applications for methacrylate-based polymers across different industries drives demand and market dynamics. In the automotive industry, methacrylate polymers are used for exterior coatings, adhesives, and impact-resistant components. In the construction industry, methacrylate-based resins are used for architectural coatings, sealants, and structural adhesives. In the electronics industry, methacrylate monomers find applications in encapsulants, optical fibers, and display materials. The wide-ranging utility of methacrylate-based polymers ensures steady demand and drives manufacturers to innovate and develop new applications, further propelling market growth.

Regulatory compliance and environmental concerns also play a crucial role in shaping the methacrylate monomers market dynamics. Governments worldwide are implementing stricter regulations aimed at reducing emissions, promoting sustainability, and ensuring the safety of materials used in various industries. Methacrylate monomers, being versatile, durable, and low-emission materials, are gaining traction as alternatives to traditional materials such as solvent-based coatings and adhesives. Manufacturers are responding to these regulatory requirements by developing methacrylate monomers that meet or exceed industry standards, thereby driving market expansion in this segment.

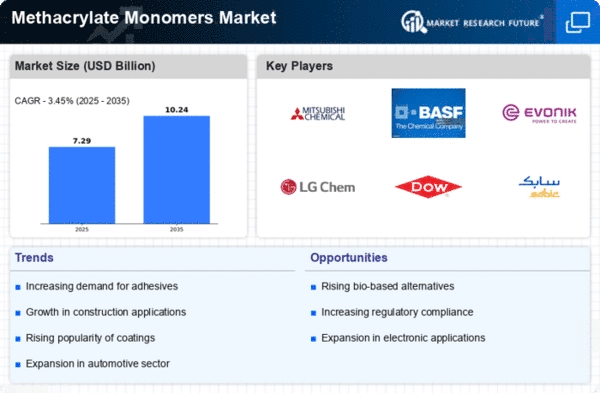

Competition within the methacrylate monomers market is intense, with several key players vying for market share. Companies differentiate themselves through product quality, innovation, technical support services, and customer relationships. Moreover, strategic partnerships, mergers, and acquisitions are common strategies employed by industry players to expand their market presence and gain a competitive edge. Additionally, pricing strategies play a crucial role in market dynamics, with manufacturers often adjusting prices in response to changes in raw material costs, competition, and market demand.

Global economic conditions and geopolitical factors also influence the methacrylate monomers market dynamics. Fluctuations in currency exchange rates, trade tariffs, and political instability can impact the cost of raw materials, transportation, and regulatory compliance, affecting both supply chains and pricing strategies. Furthermore, shifts in consumer preferences and purchasing power across different regions influence market demand and consumption patterns, driving manufacturers to adapt their strategies accordingly.

Leave a Comment