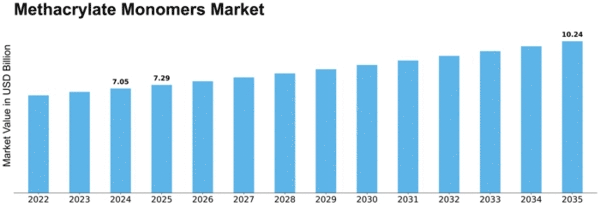

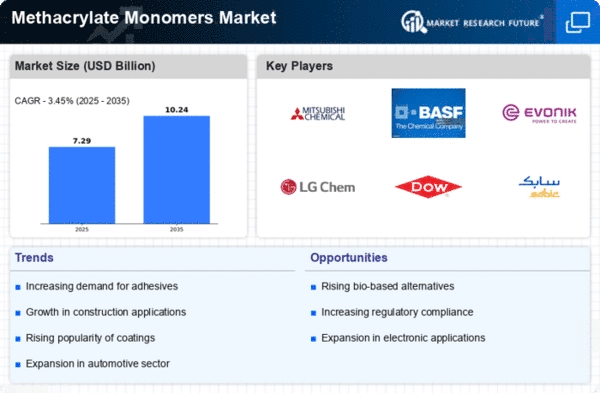

Methacrylate Monomers Size

Methacrylate Monomers Market Growth Projections and Opportunities

The methacrylate monomers market is influenced by several factors that shape its trends and growth trajectory. One of the primary drivers of this market is the widespread applications of methacrylate monomers across various industries. Methacrylate monomers serve as essential building blocks in the production of polymers, resins, coatings, adhesives, and other specialty chemicals. Their versatility, excellent adhesion, chemical resistance, and UV stability make them indispensable in industries such as automotive, construction, electronics, healthcare, and aerospace. As these industries continue to grow and innovate, the demand for methacrylate monomers remains robust, driving market growth.

Technological advancements in methacrylate monomer production processes also significantly impact the market. Manufacturers are continually innovating to develop more efficient and sustainable methods of synthesizing methacrylate monomers. Advanced catalytic processes, bio-based feedstocks, and green chemistry techniques enable the production of methacrylate monomers with higher purity, lower environmental impact, and improved performance characteristics. These technological innovations contribute to the expansion of the methacrylate monomers market by enhancing production efficiency and product quality.

Moreover, regulatory standards and environmental considerations play a vital role in shaping the methacrylate monomers market dynamics. Regulatory bodies impose strict regulations regarding the use of chemicals in various industries to ensure product safety, environmental protection, and worker health. Compliance with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and VOC (volatile organic compounds) emissions standards is essential for methacrylate monomer manufacturers to maintain market access and meet customer requirements. Additionally, growing environmental concerns about sustainability and carbon footprint drive the adoption of bio-based and renewable methacrylate monomers, further influencing market dynamics.

The competitive landscape of the methacrylate monomers market also impacts its growth trajectory. With numerous players competing for market share, competition is intense in terms of product quality, innovation, and pricing. Manufacturers invest in research and development to introduce new methacrylate monomer formulations, improve production efficiency, and develop customized solutions tailored to meet specific customer needs. Strategic collaborations, partnerships, and acquisitions are common strategies employed by companies to expand their market presence and gain a competitive edge.

Leave a Comment