Growth in Construction Activities

The ongoing expansion of construction activities across various sectors is a notable driver for the Metal Faced Insulated Panel Market. With urbanization and infrastructure development on the rise, there is a heightened need for efficient building materials. The construction sector has witnessed a surge in investments, particularly in commercial and industrial projects, which often require robust and insulated building solutions. Reports indicate that the construction industry is projected to grow at a compound annual growth rate of approximately 5% over the next few years. This growth is expected to bolster the demand for metal faced insulated panels, as they offer durability and insulation benefits that align with modern construction needs.

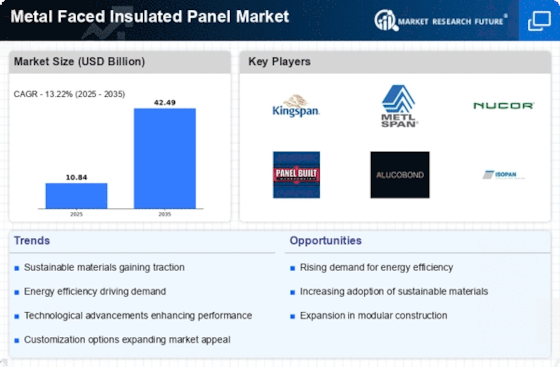

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency in construction is a primary driver for the Metal Faced Insulated Panel Market. As energy costs continue to rise, builders and developers are seeking materials that enhance thermal performance and reduce energy consumption. Metal faced insulated panels provide superior insulation properties, which can lead to significant energy savings over time. According to recent data, buildings utilizing these panels can achieve energy savings of up to 30% compared to traditional materials. This trend is likely to continue as more stakeholders prioritize sustainability and energy efficiency in their projects, thereby propelling the demand for metal faced insulated panels.

Technological Innovations in Manufacturing

Technological advancements in the manufacturing processes of metal faced insulated panels are significantly influencing the Metal Faced Insulated Panel Market. Innovations such as improved insulation materials and enhanced production techniques are leading to the development of panels that are lighter, stronger, and more efficient. These advancements not only improve the performance of the panels but also reduce production costs, making them more accessible to a wider range of consumers. Furthermore, the integration of smart technologies into these panels, such as sensors for monitoring energy efficiency, is likely to attract more buyers. As manufacturers continue to innovate, the market for metal faced insulated panels is expected to expand.

Increased Awareness of Environmental Impact

The growing awareness of environmental issues is driving the Metal Faced Insulated Panel Market as consumers and businesses alike seek sustainable building solutions. Metal faced insulated panels are often made from recyclable materials and contribute to lower carbon footprints in construction. This shift towards eco-friendly materials is being supported by various initiatives and incentives aimed at promoting sustainable building practices. As more organizations commit to reducing their environmental impact, the demand for insulated panels that align with these values is likely to increase. This trend suggests a promising future for the metal faced insulated panel market as sustainability becomes a core consideration in construction.

Regulatory Support for Energy Efficient Buildings

Regulatory frameworks promoting energy efficiency in building construction are acting as a catalyst for the Metal Faced Insulated Panel Market. Governments worldwide are implementing stricter building codes and standards that require enhanced insulation and energy performance. These regulations are designed to reduce energy consumption and greenhouse gas emissions, thereby encouraging the adoption of materials like metal faced insulated panels. As compliance with these regulations becomes mandatory, builders are increasingly turning to insulated panels to meet the required standards. This regulatory support is expected to drive market growth, as more projects will necessitate the use of energy-efficient building materials.