Cost Efficiency and Resource Optimization

Cost efficiency is becoming a pivotal driver in the 3d printed-medical-implants market. The ability to produce implants on-demand reduces inventory costs and minimizes waste, which is particularly beneficial for healthcare facilities in Italy facing budget constraints. By utilizing 3D printing technology, hospitals can significantly lower production costs, with estimates suggesting a reduction of up to 40% compared to traditional manufacturing methods. This financial advantage is encouraging more healthcare providers to invest in 3D printing capabilities, thereby expanding the market. Additionally, the potential for rapid prototyping allows for quicker iterations and adjustments, further enhancing resource optimization. As cost pressures continue to mount in the healthcare sector, the 3d printed-medical-implants market is poised for growth as facilities seek more economical solutions.

Technological Advancements in 3D Printing

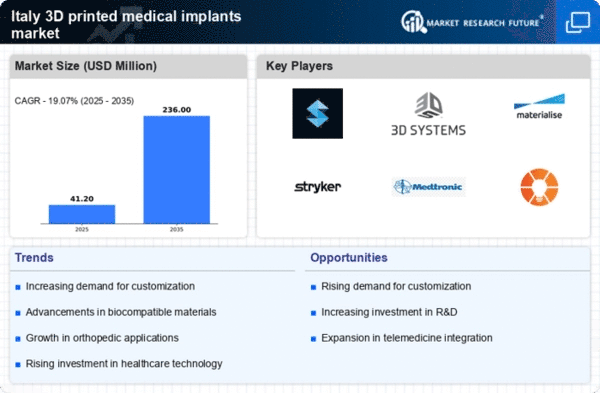

The 3d printed-medical-implants market is experiencing a surge due to rapid technological advancements in 3D printing techniques. Innovations such as bioprinting and the use of advanced materials are enhancing the precision and efficacy of medical implants. In Italy, the integration of artificial intelligence and machine learning in the design process is streamlining production, reducing costs, and improving patient outcomes. The market is projected to grow at a CAGR of approximately 25% over the next five years, driven by these technological improvements. Furthermore, the ability to create complex geometries and customized implants tailored to individual patient anatomy is revolutionizing surgical procedures, making them safer and more effective. This trend indicates a promising future for the 3d printed-medical-implants market, as healthcare providers increasingly adopt these advanced solutions.

Increased Investment in Research and Development

Investment in research and development (R&D) is a crucial driver for the 3d printed-medical-implants market. In Italy, both public and private sectors are recognizing the potential of 3D printing technologies in revolutionizing medical implants. Increased funding is being directed towards R&D initiatives aimed at exploring new materials and applications, which could lead to breakthroughs in implant design and functionality. This trend is evidenced by the establishment of collaborative partnerships between universities, research institutions, and industry players. Such collaborations are fostering innovation and accelerating the development of next-generation implants. As R&D efforts intensify, the 3d printed-medical-implants market is likely to benefit from enhanced product offerings and improved clinical outcomes, positioning it for sustained growth in the coming years.

Rising Demand for Personalized Healthcare Solutions

The growing emphasis on personalized healthcare is significantly impacting the 3d printed-medical-implants market. Patients are increasingly seeking tailored solutions that cater to their unique anatomical and physiological needs. In Italy, healthcare providers are responding to this demand by adopting 3D printing technologies that allow for the creation of customized implants. This shift is not only enhancing patient satisfaction but also improving surgical outcomes. According to recent studies, personalized implants can reduce recovery times by up to 30%, which is a compelling factor for both patients and healthcare systems. As the healthcare landscape evolves, the 3d printed-medical-implants market is likely to expand, driven by the need for individualized treatment options that align with patient preferences and clinical requirements.

Growing Awareness and Acceptance Among Healthcare Professionals

The growing awareness and acceptance of 3D printing technologies among healthcare professionals is significantly influencing the 3d printed-medical-implants market. In Italy, medical practitioners are increasingly recognizing the advantages of 3D printed implants, including their customization capabilities and improved patient outcomes. Educational initiatives and training programs are being implemented to familiarize healthcare providers with these technologies, fostering a culture of innovation within the medical community. As professionals become more adept at utilizing 3D printing in clinical settings, the adoption rate is expected to rise. This shift in perception is likely to drive demand for 3D printed implants, as healthcare providers seek to enhance their surgical practices and offer cutting-edge solutions to patients.