Rising Geriatric Population

Japan's demographic shift towards an aging population is significantly impacting the 3d printed-medical-implants market. With over 28% of the population aged 65 and older, the demand for orthopedic and dental implants is on the rise. This demographic trend necessitates the development of specialized medical implants that cater to the unique needs of older patients. The increasing prevalence of age-related conditions, such as osteoporosis and arthritis, further drives the need for innovative solutions in the medical field. Consequently, the market is expected to expand as healthcare providers seek to offer tailored solutions that improve the quality of life for the elderly, thereby enhancing the overall growth of the 3d printed-medical-implants market.

Investment in Healthcare Infrastructure

Japan's government is actively investing in healthcare infrastructure, which is likely to bolster the 3d printed-medical-implants market. Initiatives aimed at modernizing hospitals and clinics, along with the integration of advanced technologies, are creating a conducive environment for the adoption of 3D printed implants. The government has allocated substantial budgets for healthcare improvements, which include funding for research and development in medical technologies. This investment is expected to enhance the capabilities of healthcare providers, allowing them to offer cutting-edge solutions to patients. As a result, the 3d printed-medical-implants market is poised for growth, driven by improved access to advanced medical technologies.

Technological Advancements in 3D Printing

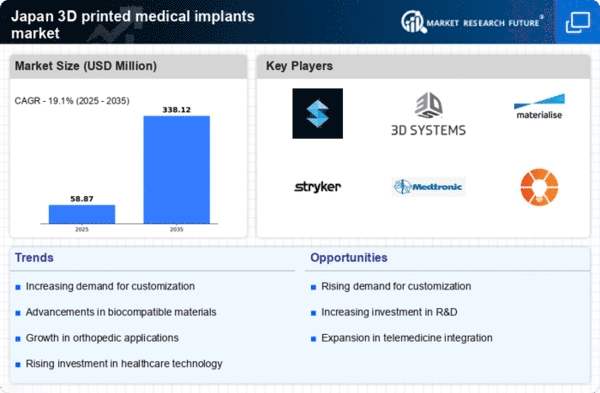

The 3d printed-medical-implants market in Japan is experiencing a surge due to rapid technological advancements in 3D printing techniques. Innovations such as bioprinting and the use of advanced materials are enhancing the quality and functionality of medical implants. For instance, the introduction of bio-compatible materials allows for better integration with human tissue, which is crucial for successful implant surgeries. Furthermore, the market is projected to grow at a CAGR of approximately 25% over the next five years, driven by these technological improvements. As hospitals and clinics adopt these advanced technologies, the demand for customized implants tailored to individual patient needs is likely to increase, further propelling the market forward.

Collaboration Between Industry and Academia

Collaboration between industry players and academic institutions is emerging as a key driver for the 3d printed-medical-implants market in Japan. These partnerships facilitate the exchange of knowledge and resources, leading to the development of innovative materials and techniques for 3D printing. Research initiatives often focus on enhancing the biocompatibility and functionality of medical implants, which is crucial for their success in clinical applications. Such collaborations are likely to accelerate the pace of innovation, enabling the market to respond effectively to evolving healthcare needs. As a result, the synergy between academia and industry is expected to play a pivotal role in shaping the future of the 3d printed-medical-implants market.

Increased Focus on Patient-Centric Solutions

The shift towards patient-centric healthcare solutions is influencing the 3d printed-medical-implants market in Japan. Healthcare providers are increasingly prioritizing personalized treatment plans that cater to individual patient needs. This trend is leading to a higher demand for customized implants that can be tailored to specific anatomical requirements. As a result, manufacturers are investing in technologies that enable the production of bespoke implants, which can enhance surgical outcomes and patient satisfaction. The emphasis on patient-centric solutions is likely to drive innovation within the market, fostering a competitive landscape that encourages the development of advanced 3D printed medical implants.