Technological Innovations in 3D Printing

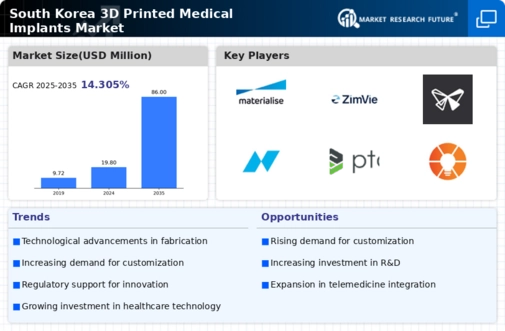

Technological innovations play a pivotal role in shaping the 3D printed medical implants market in South Korea. The introduction of advanced materials and printing techniques has significantly enhanced the quality and functionality of medical implants. For instance, the development of biocompatible materials that can mimic the properties of human tissue is revolutionizing the industry. Furthermore, the integration of artificial intelligence and machine learning in the design process is streamlining production and improving precision. As a result, the market is expected to witness a growth rate of around 12% annually, driven by these technological advancements that not only enhance the performance of implants but also reduce production costs, making them more accessible to healthcare providers.

Growing Aging Population and Chronic Diseases

The demographic shift towards an aging population in South Korea is significantly impacting the 3D printed medical implants market. As the elderly population increases, so does the prevalence of chronic diseases that often require surgical interventions and implantable devices. This demographic trend is likely to drive demand for customized medical implants that can address specific health issues faced by older adults. Projections indicate that by 2030, nearly 20% of South Korea's population will be over 65 years old, which could lead to a substantial increase in the need for orthopedic and dental implants. Consequently, the market is poised for growth as healthcare providers seek innovative solutions to meet the needs of this demographic.

Enhanced Regulatory Framework for Medical Devices

The regulatory landscape for medical devices in South Korea is evolving, which is positively influencing the 3D printed medical implants market. Recent reforms aimed at streamlining the approval process for innovative medical technologies are encouraging manufacturers to invest in 3D printing solutions. The government is actively promoting the use of advanced manufacturing techniques to enhance the competitiveness of the healthcare sector. As a result, the time to market for new products is decreasing, which may lead to a more dynamic market environment. The regulatory support is expected to facilitate a growth rate of approximately 10% in the 3d printed-medical-implants market, as companies are more inclined to develop and introduce novel implant solutions that comply with the updated regulations.

Increased Investment in Healthcare Infrastructure

The 3D printed medical implants market is benefiting from increased investment in healthcare infrastructure in South Korea. The government and private sector are channeling substantial funds into the development of advanced medical facilities and research institutions. This investment is aimed at fostering innovation and improving healthcare delivery systems. As a result, the availability of state-of-the-art equipment and technologies is enhancing the capabilities of healthcare providers to utilize 3D printing for medical implants. Reports suggest that healthcare expenditure in South Korea is expected to rise by approximately 8% annually, which could lead to a more robust market for 3d printed medical implants as facilities upgrade their capabilities to incorporate these advanced solutions.

Rising Demand for Personalized Healthcare Solutions

The 3D printed medical implants market in South Korea is experiencing a notable surge in demand for personalized healthcare solutions. This trend is driven by an increasing awareness among patients regarding the benefits of customized implants that cater to individual anatomical needs. As healthcare providers strive to enhance patient outcomes, the adoption of 3D printing technology is becoming more prevalent. Reports indicate that the market for personalized medical devices is projected to grow at a CAGR of approximately 15% over the next five years. This growth is likely to be fueled by advancements in 3D printing techniques, which allow for the creation of implants that are tailored to the unique specifications of each patient, thereby improving compatibility and reducing the risk of complications.