Rising Demand for Energy Efficiency

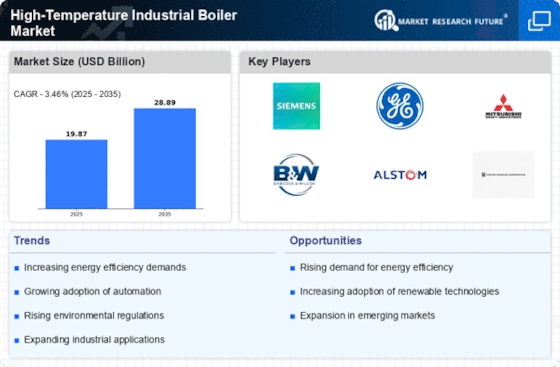

The High-Temperature Industrial Boiler Market is experiencing a notable increase in demand for energy-efficient solutions. Industries are increasingly seeking to reduce operational costs and enhance productivity, leading to a shift towards high-temperature boilers that offer superior thermal efficiency. According to recent data, energy-efficient boilers can reduce fuel consumption by up to 20%, which is a compelling incentive for manufacturers. This trend is particularly evident in sectors such as manufacturing and chemical processing, where energy costs constitute a significant portion of operational expenses. As companies strive to meet stringent energy regulations and sustainability goals, the adoption of high-temperature industrial boilers is likely to accelerate, further driving market growth.

Expansion of Industrial Applications

The High-Temperature Industrial Boiler Market is witnessing an expansion in its applications across various sectors. Industries such as food processing, pharmaceuticals, and petrochemicals are increasingly utilizing high-temperature boilers for their specific heating requirements. The versatility of these boilers allows them to cater to diverse processes, including steam generation and thermal fluid heating. Market data indicates that the food processing sector alone is projected to account for a substantial share of the market, driven by the need for precise temperature control in food production. This diversification of applications is expected to bolster the demand for high-temperature industrial boilers, as more sectors recognize their benefits.

Increased Focus on Sustainable Practices

The High-Temperature Industrial Boiler Market is experiencing a shift towards sustainable practices as industries aim to reduce their carbon footprint. The growing emphasis on environmental responsibility is prompting companies to adopt high-temperature boilers that utilize cleaner fuels and incorporate energy recovery systems. Data indicates that the adoption of sustainable boiler technologies can lead to a significant reduction in greenhouse gas emissions. As industries align their operations with sustainability goals, the demand for high-temperature industrial boilers that support these initiatives is likely to rise. This trend not only enhances corporate responsibility but also positions companies favorably in an increasingly eco-conscious market.

Regulatory Compliance and Safety Standards

The High-Temperature Industrial Boiler Market is significantly influenced by the need for compliance with stringent regulatory and safety standards. Governments and regulatory bodies are implementing rigorous guidelines to ensure safe and efficient boiler operations. This has led to an increased focus on high-temperature boilers that meet these standards, as industries seek to avoid penalties and enhance workplace safety. The market is likely to see a rise in demand for boilers that not only comply with regulations but also incorporate advanced safety features. As industries prioritize safety and compliance, the high-temperature industrial boiler market is expected to grow, driven by the need for reliable and safe heating solutions.

Technological Innovations in Boiler Design

The High-Temperature Industrial Boiler Market is benefiting from ongoing technological innovations in boiler design and functionality. Manufacturers are investing in research and development to create advanced boiler systems that offer improved performance, reliability, and efficiency. Innovations such as modular designs and smart controls are becoming increasingly prevalent, allowing for better monitoring and management of boiler operations. Market analysis suggests that these advancements could lead to a reduction in maintenance costs and downtime, making high-temperature boilers more attractive to industries. As technology continues to evolve, the market is poised for growth, driven by the demand for cutting-edge boiler solutions.