Growth in Renewable Energy Sector

The expansion of the renewable energy sector is emerging as a crucial driver for the high efficiency low voltage aluminum motors Market. As the world shifts towards sustainable energy sources, the demand for efficient motors in applications such as wind turbines and solar energy systems is increasing. High efficiency motors are essential for optimizing the performance of renewable energy systems, thereby reducing energy losses. The integration of these motors into renewable energy applications not only enhances efficiency but also supports the overall goal of reducing greenhouse gas emissions. Consequently, the High Efficiency Low Voltage Aluminum Motors Market is expected to experience growth as the renewable energy sector continues to expand.

Increased Automation in Industries

The trend towards increased automation in various industries is likely to drive the High Efficiency Low Voltage Aluminum Motors Market. As industries adopt automated systems to enhance productivity and reduce labor costs, the demand for efficient motors that can operate reliably in automated environments is rising. High efficiency motors are particularly suited for applications in robotics, conveyor systems, and automated manufacturing processes, where energy consumption and operational efficiency are critical. This shift towards automation not only improves operational efficiency but also aligns with sustainability goals, as energy-efficient motors contribute to lower energy usage. Therefore, the High Efficiency Low Voltage Aluminum Motors Market is expected to grow in tandem with the automation trend.

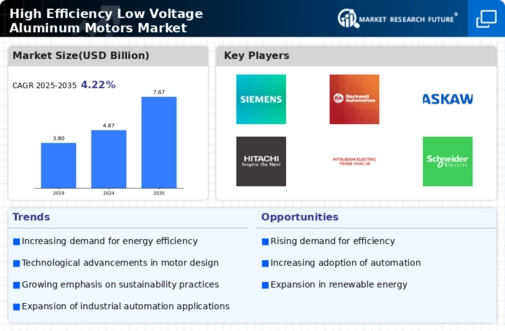

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency across various sectors appears to be a primary driver for the High Efficiency Low Voltage Aluminum Motors Market. As industries strive to reduce operational costs and comply with stringent energy regulations, the demand for energy-efficient motors has surged. According to recent data, energy-efficient motors can reduce energy consumption by up to 30%, which is particularly appealing in manufacturing and commercial applications. This trend is likely to continue, as businesses increasingly recognize the long-term savings associated with investing in high-efficiency technologies. Consequently, the High Efficiency Low Voltage Aluminum Motors Market is expected to witness substantial growth as more companies prioritize energy-efficient solutions.

Government Regulations and Incentives

Government regulations aimed at promoting energy efficiency and reducing carbon emissions are likely to significantly influence the High Efficiency Low Voltage Aluminum Motors Market. Many countries have implemented stringent standards for motor efficiency, compelling manufacturers to innovate and produce high-efficiency models. Additionally, various incentive programs, such as tax credits and rebates for energy-efficient equipment, further encourage the adoption of these motors. For instance, the implementation of the Energy Independence and Security Act has led to increased compliance requirements for electric motors, thereby driving demand in the market. As regulatory frameworks evolve, the High Efficiency Low Voltage Aluminum Motors Market is poised for growth, driven by compliance and incentives.

Technological Innovations in Motor Design

Technological advancements in motor design and materials are transforming the High Efficiency Low Voltage Aluminum Motors Market. Innovations such as improved rotor designs, advanced magnetic materials, and enhanced cooling techniques contribute to higher efficiency and performance. For example, the introduction of permanent magnet synchronous motors has shown to enhance efficiency levels significantly. These innovations not only improve energy consumption but also extend the lifespan of motors, making them more appealing to end-users. As manufacturers continue to invest in research and development, the High Efficiency Low Voltage Aluminum Motors Market is likely to benefit from a steady influx of cutting-edge technologies that enhance motor performance.