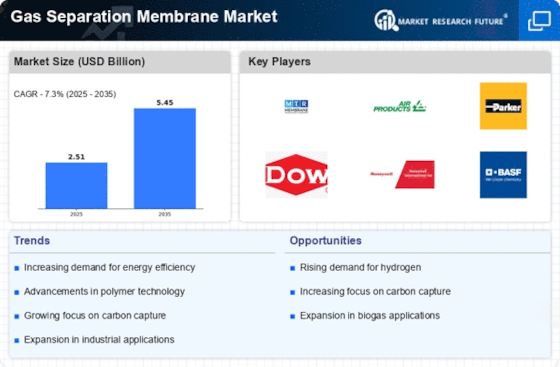

Market Share

Gas Separation Membrane Market Share Analysis

Businesses use a variety of tactics in the gas separation membrane industry to protect and grow their market share. These strategic initiatives play a critical role in helping businesses that depend on gas separation technology navigate the competitive landscape and meet their changing demands. An examination of the primary market share positioning techniques used by participants in the gas separation membrane sector is provided below: Technology Advancements: Creative Membrane Designs: Businesses concentrate on creating state-of-the-art membrane technologies that provide exceptional gas separation capabilities. This entails funding R&D to produce membranes with improved durability, permeability, and selectivity, establishing the business as a leader in technology. Integration of Advanced Materials: The development of high-performance membranes is aided by the use of advanced materials, such as polymers with superior gas separation capabilities. This technical advantage enables businesses to satisfy the demanding needs of a range of sectors, including healthcare and petrochemicals. Solution tailored to an application: Custom Membranes for Different Industries: Companies customize their membrane solutions for certain sectors because they understand the wide range of uses for gas separation. By tailoring membranes to the particular requirements of air separation, hydrogen recovery, or natural gas processing, they establish themselves as specialist suppliers. Geographical Considerations: Businesses modify their products to meet the unique needs of various markets by taking into account geographical variances in gas composition and separation requirements. Their competitive advantage in every area is increased by this focused strategy. Strategic Alliances:

Collaboration with End-users: Establishing alliances with end-users, such petrochemical or energy firms, promotes cooperation and guarantees the creation of solutions that correspond with real industry demands. This tactic aids in the development of customized membrane solutions that meet the operational needs of the end customers. Cooperation with Research Institutions: Access to the most recent scientific developments is facilitated by collaboration with academic institutions and research institutes. Joint research projects improve a company's standing in the market and aid in the creation of novel membrane technologies. Economical Production: Expanded Production: Cost leadership in membrane manufacture requires achieving economies of scale in the production process. Businesses spend in expanding their manufacturing operations in order to lower the cost of production per unit and increase the price attractiveness of their products.

Leave a Comment