Growth in the E-commerce Sector

The Flexible Filament 3D Printing Material Market is significantly influenced by the rapid expansion of the e-commerce sector. As online shopping continues to gain traction, there is an increasing demand for on-demand manufacturing solutions that can cater to consumer preferences. Flexible filaments are particularly well-suited for this purpose, as they enable the production of lightweight, durable, and customizable products that can be shipped directly to consumers. Recent statistics indicate that the e-commerce market is projected to grow at a CAGR of 18% over the next five years, creating a favorable environment for flexible filament applications. This growth is likely to encourage manufacturers to invest in 3D printing technologies that utilize flexible materials, thereby enhancing their product offerings and meeting the evolving needs of consumers. Consequently, the industry is poised for substantial growth as it aligns with the trends in e-commerce.

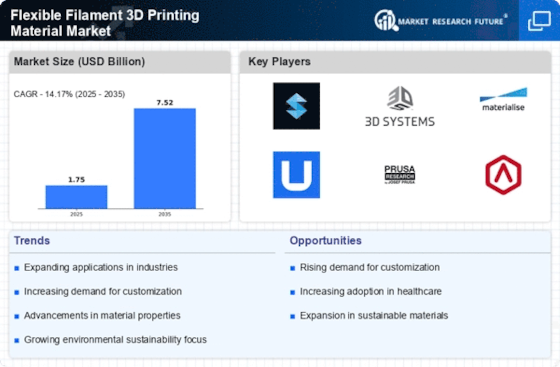

Rising Demand for Customization

The Flexible Filament 3D Printing Material Market experiences a notable surge in demand for customized products across various sectors. As consumers increasingly seek personalized solutions, manufacturers are compelled to adopt flexible filament materials that allow for intricate designs and tailored functionalities. This trend is particularly evident in industries such as automotive and healthcare, where bespoke components are essential. According to recent data, the customization segment is projected to grow at a compound annual growth rate (CAGR) of approximately 15% over the next five years. This growth is indicative of a broader shift towards individualized production methods, which are facilitated by the unique properties of flexible filaments, such as elasticity and durability. Consequently, the industry is likely to witness an expansion in the range of applications for flexible filaments, further driving market growth.

Expanding Industrial Applications

The Flexible Filament 3D Printing Material Market is experiencing a notable expansion in industrial applications. Industries such as aerospace, automotive, and consumer goods are increasingly adopting flexible filaments for prototyping and production purposes. The unique properties of flexible materials, such as their ability to withstand stress and strain, make them ideal for creating functional prototypes and end-use parts. Recent data suggests that the industrial segment of the 3D printing market is projected to grow at a CAGR of 22% over the next five years. This growth is driven by the need for rapid prototyping and the ability to produce complex geometries that traditional manufacturing methods cannot achieve. Consequently, the industry is likely to see a rise in demand for flexible filaments as manufacturers seek to enhance their production capabilities and innovate their product lines.

Increased Focus on Sustainability

Sustainability initiatives are becoming increasingly prominent within the Flexible Filament 3D Printing Material Market. As environmental concerns rise, manufacturers are seeking eco-friendly materials that minimize waste and reduce carbon footprints. Flexible filaments made from biodegradable or recycled materials are gaining popularity, as they align with the growing demand for sustainable production practices. Market analysis indicates that the segment of sustainable 3D printing materials is expected to witness a growth rate of approximately 25% over the next few years. This shift towards sustainability not only addresses consumer preferences but also complies with regulatory pressures aimed at reducing environmental impact. As a result, the industry is likely to see a diversification of flexible filament offerings, catering to environmentally conscious consumers and businesses alike.

Advancements in 3D Printing Technology

Technological innovations play a pivotal role in shaping the Flexible Filament 3D Printing Material Market. Recent advancements in 3D printing technologies, including improved extrusion processes and enhanced printer capabilities, have significantly broadened the scope of flexible filament applications. For instance, the introduction of multi-material printing techniques allows for the combination of flexible filaments with rigid materials, resulting in hybrid products that exhibit superior performance characteristics. Market data suggests that the adoption of advanced 3D printing technologies is expected to increase by 20% in the coming years, thereby enhancing the overall efficiency and quality of printed products. This technological evolution not only boosts production speed but also reduces material waste, aligning with sustainability goals. As a result, the industry is likely to see a heightened interest in flexible filaments, driven by the need for innovative solutions in various manufacturing processes.