Market Analysis

In-depth Analysis of Engineered Plastics Market Industry Landscape

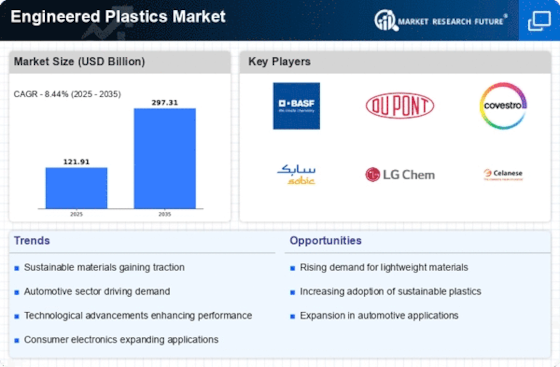

The engineered Plastics market landscape has been shaped by dynamic multidimensional forces characterized by its multilateral nature. These are polymer materials with enhanced properties designed to meet specific requirements; hence, they can also be termed high-performance plastics or engineered plastics. One driver that underpins The Engineered Plastics market growth trajectory is the constant demand for lightweight and durable materials in different sectors. For example, sectors such as automotive, aerospace, and electronics are on the lookout for materials that have a high strength-to-weight ratio, corrosion resistance, and enhanced performance levels. Market dynamics are significantly influenced by innovation, with manufacturers seeking new formulations and applications for engineered plastics. In this regard, research and development focus on improving the material's thermal stability, chemical resistance, and flame retardancy, thus expanding its use in more industries. Moreover, engineered plastics can replace traditional materials like glass or metal in critical applications, which further stimulate their marketability worldwide. Furthermore, the Engineered Plastics market has also been impacted by the global push towards sustainability. Accordingly, they carry out research on bio-based engineered plastics due to the increasing preference for eco-friendly and recyclable components. Growing awareness about the environment and regulations that protect it has influenced both customer preferences and industrial practices, too. Despite these changing market conditions, there are several challenges associated with them. Fluctuations in raw material prices often related to the petrochemical industry may affect the overall cost of producing engineered plastics. These issues can lead to price volatility because of economic uncertainty or geopolitical factors, thereby influencing the profitability of players in the sector, much as stringent regulation limiting the use of specific chemicals in plastic manufacturing could pose compliance challenges calling for investments into alternative formulations meeting regulatory standards. Again, its dynamic characteristics are due to how the engineered plastics market is geographically distributed. The expanding manufacturing sectors in emerging economies offer substantial growth prospects fueled by industrialization and infrastructure development. Hence, market participants should negotiate through a wide range of rules and regulations that differ from one country to another, as well as cultural differences and a variety of consumer demands, so as to create a strong presence in these areas.

Leave a Comment