Sustainability Initiatives

Sustainability initiatives are becoming increasingly pivotal within the Braze Alloys Market. As environmental concerns gain prominence, manufacturers are compelled to adopt eco-friendly practices and materials. The shift towards sustainable production methods, such as the use of recyclable materials and energy-efficient processes, is influencing the development of new braze alloys. This trend is not only beneficial for the environment but also aligns with regulatory requirements that are becoming more stringent. Companies that prioritize sustainability are likely to gain a competitive edge, as consumers and businesses alike are increasingly favoring environmentally responsible products. The Braze Alloys Market is thus witnessing a shift towards greener alternatives, which may lead to the emergence of innovative, sustainable alloy formulations that meet both performance and environmental standards.

Growing Demand in Emerging Markets

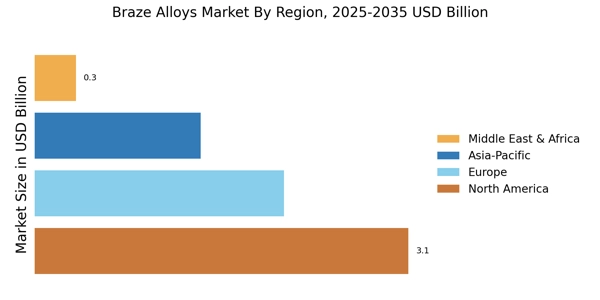

The Braze Alloys Market is witnessing a surge in demand from emerging markets, driven by rapid industrialization and urbanization. Countries in Asia-Pacific and Latin America are experiencing significant growth in sectors such as automotive, aerospace, and electronics, which are major consumers of braze alloys. For instance, the automotive industry in these regions is expanding, leading to increased requirements for high-performance brazing solutions. This trend is expected to propel the demand for braze alloys, as manufacturers seek reliable and efficient materials to meet the needs of these burgeoning industries. Additionally, the rise of local manufacturing capabilities in these markets is likely to further stimulate growth in the Braze Alloys Market, as companies invest in advanced technologies and processes to enhance their production capabilities.

Rising Applications in Electronics

The Braze Alloys Market is significantly influenced by the rising applications of brazing in the electronics sector. As electronic devices become more compact and complex, the need for reliable and efficient joining methods is paramount. Brazing offers distinct advantages, such as the ability to join dissimilar metals and create strong, durable connections. The increasing demand for consumer electronics, including smartphones, laptops, and wearable devices, is driving the need for high-quality braze alloys. Furthermore, advancements in electronic components, such as heat sinks and circuit boards, are creating new opportunities for brazing applications. This trend suggests that the Braze Alloys Market will continue to expand as manufacturers seek innovative solutions to meet the evolving demands of the electronics sector.

Regulatory Compliance and Standards

Regulatory compliance and standards are becoming increasingly critical in the Braze Alloys Market. As industries face heightened scrutiny regarding product safety and environmental impact, adherence to established regulations is essential. Manufacturers are required to comply with various international standards, which dictate the composition and performance of braze alloys. This compliance not only ensures product quality but also enhances marketability. Companies that proactively align their products with these regulations are likely to gain consumer trust and market share. Additionally, the ongoing development of new standards may drive innovation within the Braze Alloys Market, as manufacturers seek to create alloys that meet or exceed these evolving requirements. This focus on compliance is expected to shape the future landscape of the market.

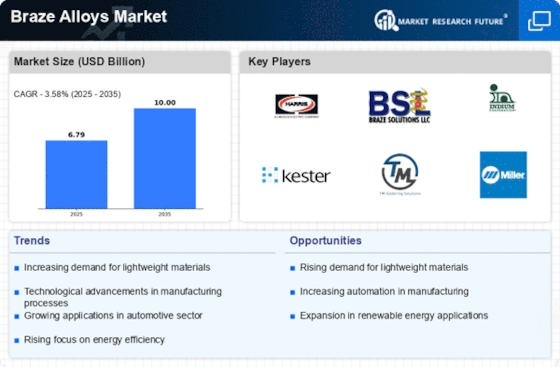

Technological Advancements in Manufacturing

The Braze Alloys Market is experiencing a notable transformation due to advancements in manufacturing technologies. Innovations such as automated brazing processes and improved alloy compositions are enhancing the efficiency and effectiveness of brazing operations. These technological improvements not only reduce production costs but also increase the quality and reliability of the final products. For instance, the introduction of laser brazing techniques has been shown to provide superior joint strength and precision. As manufacturers adopt these advanced technologies, the demand for high-performance braze alloys is likely to rise, thereby driving growth in the Braze Alloys Market. Furthermore, the integration of Industry 4.0 principles, including smart manufacturing and data analytics, is expected to optimize production processes, leading to increased competitiveness in the market.