Rising Demand in Automotive Sector

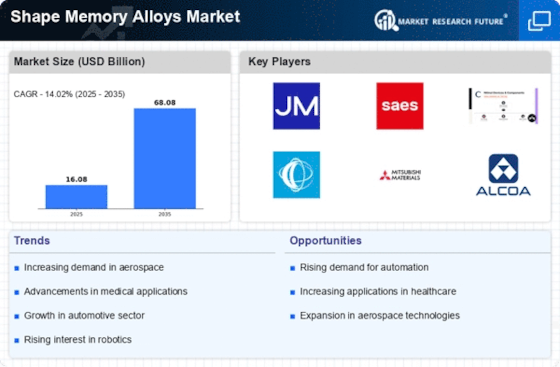

The automotive industry is increasingly integrating advanced materials to enhance vehicle performance and efficiency. Shape Memory Alloys Market is experiencing a surge in demand as manufacturers seek lightweight and durable components. These alloys offer unique properties such as the ability to return to a predetermined shape when heated, which can be utilized in various applications, including actuators and sensors. The automotive sector's shift towards electric vehicles further propels the need for innovative materials that can withstand extreme conditions while reducing weight. As a result, the Shape Memory Alloys Market is projected to witness substantial growth, with estimates suggesting a compound annual growth rate of over 10% in the coming years.

Increased Use in Robotics and Automation

The rise of robotics and automation is significantly impacting the Shape Memory Alloys Market. These alloys are being utilized in actuators and mechanisms that require precise movement and control. Their unique ability to change shape in response to temperature variations makes them ideal for applications in soft robotics and automated systems. As industries increasingly adopt automation to enhance efficiency and reduce labor costs, the demand for shape memory alloys is expected to grow. This trend is particularly evident in manufacturing and logistics, where the integration of advanced materials can lead to improved operational performance. The Shape Memory Alloys Market is likely to see a robust increase in demand driven by these technological advancements.

Expanding Applications in Medical Devices

The medical device sector is a prominent driver for the Shape Memory Alloys Market. These materials are increasingly used in various medical applications, including stents, guidewires, and surgical instruments, due to their biocompatibility and unique mechanical properties. The ability of shape memory alloys to return to a specific shape at body temperature enhances the functionality of medical devices, making procedures less invasive and more effective. As the healthcare industry continues to innovate and seek advanced solutions for patient care, the demand for shape memory alloys is expected to rise. Market analysts project that the medical applications segment will contribute significantly to the overall growth of the Shape Memory Alloys Market in the coming years.

Technological Advancements in Manufacturing

Technological innovations in the production of shape memory alloys are significantly influencing the Shape Memory Alloys Market. Advanced manufacturing techniques, such as additive manufacturing and precision casting, are enabling the creation of more complex and efficient alloy structures. These advancements not only improve the performance characteristics of the alloys but also reduce production costs, making them more accessible to various industries. Furthermore, the development of new alloy compositions enhances the thermal and mechanical properties, broadening the scope of applications. As industries increasingly adopt these technologies, the Shape Memory Alloys Market is likely to expand, with a focus on high-performance applications in sectors such as robotics and aerospace.

Growing Investment in Research and Development

Investment in research and development is a critical driver for the Shape Memory Alloys Market. As industries recognize the potential of these materials, funding for innovative applications and new alloy formulations is increasing. Research initiatives are focusing on enhancing the properties of shape memory alloys, such as fatigue resistance and thermal stability, which are essential for high-stress applications. This influx of investment is expected to lead to breakthroughs that could unlock new markets and applications, particularly in sectors like healthcare and aerospace. The Shape Memory Alloys Market stands to benefit from these advancements, as they may lead to the introduction of next-generation products that meet evolving consumer demands.