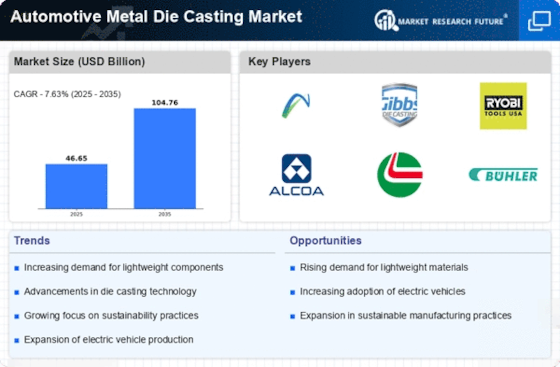

Top Industry Leaders in the Automotive Metal Die Casting Market

June 2023

Die-casting expert Bühler is using Open House Day at its Austrian facility to introduce a new megacasting machine to the European market. The Carat 840 behemoth combines improved emissions and material sustainability with its massive casting capabilities.

The Carat 840 gets its name from its 8,400-ton locking force. The device has a height of 25 feet and a floor area of about 525 square feet. In milliseconds, it can inject more than 440 pounds (200 kg) of liquid aluminum into a die. Megacasting technology allows for the replacement of between 70 and 100 parts with a single die-cast part. These one-piece castings are made close to the vehicle assembly line to allow for improved integration and reduced transportation.

Aluminum castings are said to have the ability to cut CO2-equivalent emissions by 70% in addition to their reduced complexity. This can be accomplished by melting aluminum alloys with a low carbon footprint, switching to renewable electricity for all operations, and avoiding the use of fossil fuels.

September 2023

Tesla has made significant progress towards realising single-piece car casting, a la Hot Wheels. To produce car bodies in a small number of large parts rather than hundreds, Tesla has made significant investments in large casting technology in recent years.

Known as "Gigapress," the automaker currently runs several of the biggest casting machines in the world. In order to manufacture the front and rear castings for the Model Y, Tesla had a new 9,000-ton press built specifically for making Cybertruck parts, pushing the boundaries of casting technology.

Major players in the automotive metal die casting market, including GF Casting Solutions AG (Switzerland), Minda Corporation Limited (India), Tadir-Gan Group (Israel), PHB Corp. (US) and others, are attempting to increase market demand by investing in R&D operations.