Market Trends

Key Emerging Trends in the Automotive Magnet Wire Market

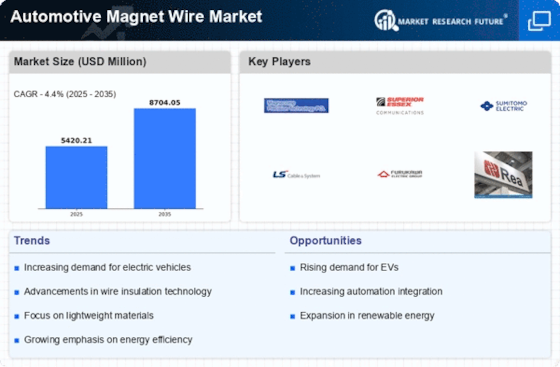

The Automotive Magnet Wire Market is going through massive transformation process breathing with the rising trend of electric and hybrid vehicles amidst increasing electrification of cars. The magnet wire or better known as winding wire, is one of the most important components that is involved in electric motors, transformers as well as coils present in automotive systems. One of the very evident features of the market at the moment is increase in the manufacturing of electric vehicles(EVs). Just like automotive industry is rapidly integrating with sustainable and electric cars the world is already witnessing increased demand for magnet wire used because of electric motor windings. Such findings mirror global efforts to curb growing greenhouse emissions and the increasing global efforts of the adoption of EVs.

In addition, other market segments such as electric power steering systems are experiencing strong growth, which is creating a growing demand for automotive magnet wire. Electric power steering (EPS) is one of the well-known technologies that utilize magnet wire in their motor windings to supply great and accurate control over the steering mechanisms. Currently, the demand for magnet wire in automotive applications is increasing as the EPS based vehicles are into production for better fuel efficiency and better driving experience. These are reflections of the ever-ongoing inventions in the dynamic of the vehicles and also a shift towards the use of more advanced and electronically control steering systems.

Furthermore, high-temperature-resistant magnet wires are increasing in popularity, and hence their use in vehicle magnet wires is also increasing. With the introduction of electric vehicles some of them which turn out to be highly tuned electric sports cars we need magnet wires which are able to stand high temperatures generated during operation. High-temperature magnet wires with the main function of providing durability and reliability to electric motors at high temperature in automotive environments are the main component. This trend is in line with the pursuit of power and life in electric control systems and in vehicles of premium and acceptance of purely electric vehicle.

Apart from that, the growing demand for automotive magnet wire is another factor that is stimulated by the surge in adopting the electric traction motors for hybrid cars. Hybrid cars are vehicles that have electric motors aside traditional internal combustion engine and magnate wire is utility item in these motors working at high efficiencies. The growth of the hybrid vehicles market which takes precedence due to the need for improved fuel efficiency and less emissions favors the automotive part applications of magnet wire. This pattern denotes the problems magnet wires are facing because of their necessity to support hybrid powertrains and the move to more green motor vehicles.

Leave a Comment