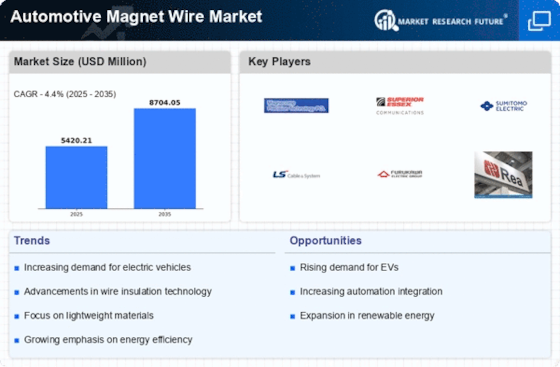

Top Industry Leaders in the Automotive Magnet Wire Market

The automotive magnet wire market is a dynamic and growing industry driven by the increasing demand for EVs, HEVs, and ADAS. Leading players are adopting various strategies to compete effectively and gain market share. Technological advancements, regulatory changes, and sustainability concerns are shaping the future of the market. Continued innovation and investment in research and development will be key to success in this promising field.

Strategies for Market Share Dominance:

Leading players in the automotive magnet wire market employ diverse strategies to gain and retain market share. Here are some prominent ones:

-

Product Innovation: Companies like Hitachi Metals and TE Connectivity invest heavily in research and development, constantly improving insulation materials, temperature resistance, and miniaturization to cater to the evolving demands of electric vehicles. -

Vertical Integration: Some brands like Nexans and Sumitomo Electric establish control over various stages of the production chain, from raw material sourcing to finished wire processing, ensuring quality and cost-effectiveness. -

Geographical Expansion: Established players like Fujikura expand their reach into high-growth regions like China and India, capitalizing on the burgeoning automotive production in these areas. -

Strategic Partnerships: Collaborations with automakers and tier-1 suppliers are crucial for securing long-term contracts and technical insights. Examples include Magna's partnership with Fujikura and Delphi's collaboration with TE Connectivity. -

Sustainability Focus: Eco-friendly product development, responsible sourcing, and reduced waste generation are gaining prominence as companies like Molex and Unex Corporation cater to increasing customer demand for sustainable practices.

Factors Influencing Market Share:

Multiple factors influence market share distribution in the automotive magnet wire market:

-

Quality and Reliability: Consistent performance and adherence to rigorous automotive standards are essential for winning trust and long-term contracts. -

Cost Competitiveness: Balancing quality with affordable pricing is crucial, especially in price-sensitive regions. -

Technological Expertise: The ability to cater to new technologies like high-voltage systems and miniaturized motors can provide a competitive edge. -

Geographical Presence: Having production facilities and distribution networks close to major automotive hubs reduces logistic costs and improves delivery times. -

Customer Relationships: Building strong relationships with automakers and tier-1 suppliers through technical support and innovative solutions is vital for securing market share.

Key Companies in the Automotive Magnet Wire market include

- MWS Wire Industries (MWS)

- Superior Essex Inc.

- Elektrisola Dr. Gerd Schildbach GmbH & Co KG

- Tongling Jingda Special Magnet Wire Co., Ltd

- Proterial Ltd

- Sam Dong

- Tongling Jingda Special Magnet Wire Co., Ltd.

- Proterial Ltd, formerly Hitachi Metals, Ltd.

- Sumitomo Electric Industries, Ltd.

- Fujikura Ltd.

- LWW Group

- SHWire

Industry News

-

July 2023: Sumitomo Electric announced the development of a new high-temperature magnet wire specifically designed for EV motors, capable of withstanding extreme operating conditions. -

August 2023: Lapp Group signed a partnership agreement with a major Chinese automotive manufacturer to supply magnet wire for their upcoming electric vehicle production line. -

September 2023: The Winding Wire Market announced the expansion of its production facility in North America to meet the growing demand for magnet wire in the region.