Supportive Regulatory Framework

A supportive regulatory framework is emerging as a vital driver for the 3D Printed Maxillofacial Implant Market. Regulatory bodies are increasingly recognizing the potential of 3D printed medical devices, leading to the establishment of guidelines that facilitate their approval and use. This regulatory support is crucial for manufacturers, as it provides a clearer pathway for bringing innovative products to market. The establishment of standards for safety and efficacy is likely to enhance consumer confidence, thereby driving demand. As regulations continue to evolve, they are expected to foster innovation and encourage investment in the development of advanced maxillofacial implants.

Increasing Incidence of Facial Trauma

The rising incidence of facial trauma, due to accidents and sports injuries, is a critical driver for the 3D Printed Maxillofacial Implant Market. According to recent statistics, facial injuries account for a significant percentage of all trauma cases, necessitating effective treatment solutions. The demand for personalized implants that can be precisely fitted to the unique anatomy of each patient is growing. This trend is likely to propel the market forward, as healthcare providers seek innovative solutions to address the complexities of facial reconstruction. The ability of 3D printing to produce patient-specific implants is expected to enhance surgical outcomes and patient satisfaction.

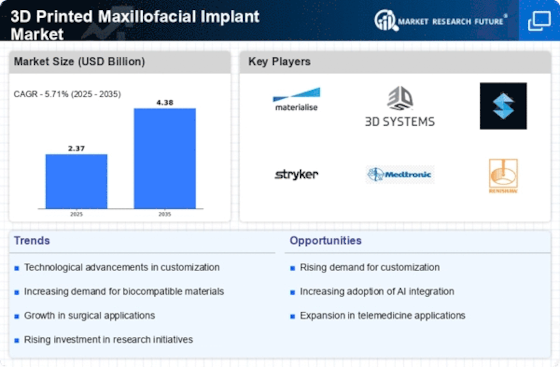

Advancements in 3D Printing Technology

Technological advancements in 3D printing are significantly influencing the 3D Printed Maxillofacial Implant Market. Innovations such as biocompatible materials and improved printing techniques are enabling the production of highly precise and durable implants. The market for 3D printing in healthcare is expected to grow at a compound annual growth rate of around 20% over the next few years. These advancements not only enhance the quality of implants but also reduce production costs and time, making them more accessible to healthcare providers. As technology continues to evolve, it is anticipated that the market will witness an influx of new products and solutions tailored to meet diverse patient needs.

Rising Demand for Aesthetic Procedures

The increasing emphasis on aesthetic procedures is a notable driver for the 3D Printed Maxillofacial Implant Market. Patients are increasingly seeking solutions that not only restore functionality but also enhance appearance. This trend is reflected in the growing number of cosmetic surgeries, which has been projected to reach a market value of approximately 66 billion USD by 2026. As a result, the demand for customized maxillofacial implants, which can be tailored to individual facial structures, is likely to rise. This shift towards aesthetic enhancement is pushing manufacturers to innovate and develop more sophisticated 3D printed implants, thereby expanding the market's potential.

Growing Awareness of Personalized Medicine

The growing awareness of personalized medicine is significantly impacting the 3D Printed Maxillofacial Implant Market. Patients are becoming more informed about their treatment options and are increasingly seeking personalized solutions that cater to their specific needs. This shift towards individualized care is prompting healthcare providers to adopt advanced technologies, including 3D printing, to create tailored implants. The market for personalized medicine is projected to reach over 2 trillion USD by 2030, indicating a robust growth trajectory. As awareness continues to rise, the demand for customized maxillofacial implants is likely to increase, driving innovation and competition within the industry.