Sustainability Initiatives

Sustainability initiatives are becoming increasingly pivotal within the Wire Rolling Machine Market. As environmental regulations tighten, manufacturers are compelled to adopt eco-friendly practices. This includes the use of energy-efficient machines and the implementation of recycling processes for scrap materials. Recent studies indicate that companies focusing on sustainable manufacturing practices can reduce their operational costs by up to 15%. Furthermore, the demand for sustainable products is rising, with consumers showing a preference for companies that prioritize environmental responsibility. This trend is likely to propel the Wire Rolling Machine Market towards greener technologies, fostering innovation and attracting investment.

Growth of Renewable Energy Sector

The growth of the renewable energy sector is emerging as a vital driver for the Wire Rolling Machine Market. As countries strive to meet renewable energy targets, the demand for wire products used in solar panels, wind turbines, and other renewable technologies is on the rise. Recent statistics indicate that the renewable energy market is expected to expand by over 15% annually, which will likely increase the need for specialized wire rolling machines. This trend not only supports the Wire Rolling Machine Market but also aligns with global efforts to transition towards sustainable energy solutions, fostering innovation and investment in this sector.

Infrastructure Development Projects

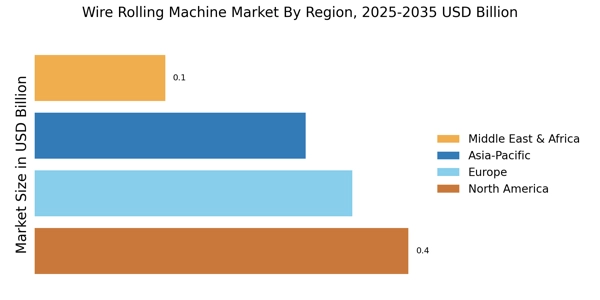

Infrastructure development projects are a crucial catalyst for the Wire Rolling Machine Market. Governments and private entities are investing heavily in infrastructure, including roads, bridges, and buildings, which necessitates a substantial amount of wire products. Recent reports indicate that infrastructure spending is projected to increase by 10% annually, creating a robust demand for wire rolling machines. This trend is particularly evident in emerging markets, where urbanization is driving the need for enhanced infrastructure. Consequently, the Wire Rolling Machine Market stands to benefit significantly from these developments, as manufacturers ramp up production to meet the growing requirements.

Rising Demand from Automotive Sector

The automotive sector is a significant driver for the Wire Rolling Machine Market, as the demand for high-quality wire products continues to surge. With the automotive industry increasingly focusing on lightweight materials to enhance fuel efficiency, the need for specialized wire rolling machines is expected to grow. Data suggests that the automotive sector accounts for nearly 30% of the total demand for wire products, which in turn stimulates the Wire Rolling Machine Market. As electric vehicles gain traction, the requirement for advanced wiring solutions will further bolster this market, indicating a robust growth trajectory in the coming years.

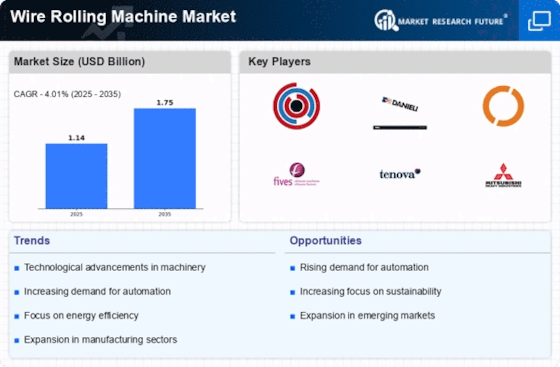

Technological Advancements in Manufacturing

The Wire Rolling Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as automation and smart manufacturing are enhancing production efficiency and precision. For instance, the integration of IoT technology allows for real-time monitoring and predictive maintenance, which can reduce downtime and operational costs. According to recent data, the adoption of advanced manufacturing technologies is projected to increase productivity in the wire rolling sector by approximately 20% over the next five years. This shift not only improves the quality of the final products but also enables manufacturers to respond swiftly to market demands, thereby driving growth in the Wire Rolling Machine Market.