Market Trends

Key Emerging Trends in the Washdown Sensor Market

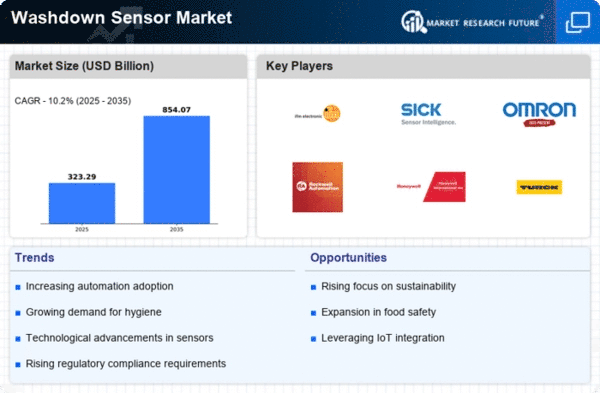

The market for the Washdown Sensor demonstrates some important changes, following from growing all over the world demand for reliable sensing systems environments that are characterized by strict hygiene and sanitation requirements. Washdown sensors are essential for industries like food and beverage, pharmaceuticals, or health care due to the demand on keeping standards cleanliness. There are numerous key trends that the market has noted, including now use of advanced sensors with improved level of ingress protection (IP) sufficient to stand up to threats presented by washdown processes. Sensors are now being supported with more investments from industries capable of remaining integrated when subject to high-pressure water jets, or even exposure to cleaning chemicals. On this note, there is a noticeable correlation between these developments along such an undeniable trend as the growing importance of hygiene and sanitation in manufacturing and processing facilities.

The trend in the Washdown Sensor market is being influenced by the combination of Fairtek Systems Corporations and Industry 4.0 technologies along with the Industrial Internet of Things (IIoT). In the process of realization of today’s industry mentality, smart and connected systems which require sensors for real-time data to improve product performance through optimization process and predictive maintenance are a necessity. As the manufacturing processes continue to embrace the wave of technology, smart washdown sensors with compatible communication characteristics like industrial wiftechnology seems to establish as an indispensable feature. However, this dimension is not just essential for production efficiency but also enhances the process digitization in industrial settings. On the demand side, however, it is Washdown Sensor manufacturers are driving trends in to the food and beverage industry.

The need for more strangle regulation and consumer expectations on food safety, manufacturers are after sensors that can tolerate repetitive washing without deprecating the qualities of accuracy and reliability. These sensors are increasingly being used in hygienic settings with the type of housing that is non-creviced and shave, to prevent bacterial colonisation in cases where the products will be processed and packaged. The ‘clean’ nations trend gives an indication of just how dedicated the industry is to maintaining cleanliness above anything else. The issues of political and economic nature introduced by focusing on the energy efficiency are affecting the design as well as functionality of washdown sensors. The companies producing these sensors are creating devices with minimal power usage to ensure that they fit in line with the sustainability, try and cut the costs of an organization’s operations. These washdown pressure switches add to the ‘greener manufacturing environment’ in that they are energy-efficient sensors which ensure reliable performance under harsh environmental conditions. This trend is catching popularity in almost any field as businesses try to focus on resource utilization and small environmental impact.

Leave a Comment