Growth in Construction Activities

The sandwich panel market is benefiting from the robust growth in construction activities across various sectors, including commercial, residential, and industrial. The US construction industry is projected to reach a value of $1.8 trillion by 2026, with sandwich panels playing a crucial role in modern building practices. Their lightweight nature and ease of installation contribute to reduced labor costs and construction time. As more developers recognize the advantages of using sandwich panels, the market is likely to see increased adoption. This growth in construction activities is expected to drive the demand for sandwich panels, as they offer a combination of durability and efficiency that aligns with contemporary building requirements.

Increased Focus on Prefabrication

The market is witnessing a shift towards prefabrication in construction, which is gaining traction in the US.. Prefabricated building components, including sandwich panels, allow for faster assembly and reduced waste on construction sites. This method aligns with the industry's push for efficiency and sustainability. Reports indicate that the prefabricated construction market is expected to grow by over 10% annually, with sandwich panels being a key component. The ability to manufacture panels off-site and transport them for quick installation is appealing to builders looking to streamline processes. This trend suggests that the sandwich panel market will continue to expand as prefabrication becomes more mainstream.

Rising Demand for Energy Efficiency

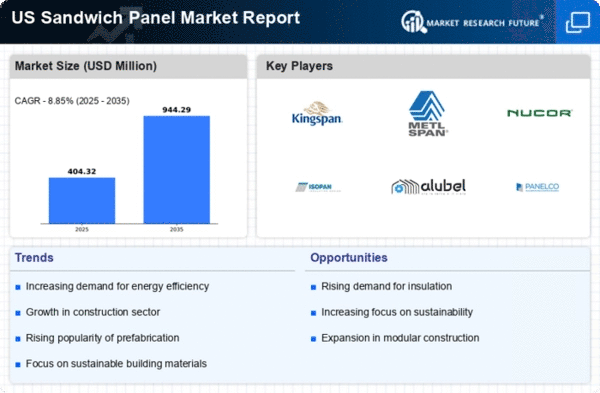

The sandwich panel market is experiencing a notable increase in demand for energy-efficient building materials. As energy costs continue to rise, consumers and businesses are seeking solutions that reduce energy consumption. Sandwich panels, known for their excellent thermal insulation properties, are becoming a preferred choice in construction. In the US, the energy efficiency of buildings is a critical concern, with regulations pushing for lower energy usage. The market for sandwich panels is projected to grow at a CAGR of approximately 6% over the next few years, driven by this demand for sustainable and energy-efficient solutions. This trend indicates a shift towards materials that not only meet regulatory standards but also provide long-term cost savings for end-users.

Technological Innovations in Manufacturing

The sandwich panel market is experiencing a wave of technological innovations that enhance manufacturing processes and product quality. Advances in materials science and production techniques are enabling manufacturers to create panels that are lighter, stronger, and more energy-efficient. In the US, the integration of automation and smart technologies in production lines is streamlining operations and reducing costs. This innovation is crucial as it allows manufacturers to meet the increasing demand for high-performance sandwich panels. As technology continues to evolve, the market is expected to benefit from improved product offerings, which could lead to greater market penetration and consumer acceptance.

Regulatory Support for Sustainable Materials

The sandwich panel market is positively influenced by increasing regulatory support for sustainable building materials in the US. Government initiatives aimed at promoting green construction practices are encouraging the use of materials that minimize environmental impact. Sandwich panels, which often incorporate recyclable materials and offer energy efficiency, align well with these regulations. As more states adopt stringent building codes that favor sustainable options, the market for sandwich panels is likely to grow. This regulatory environment not only supports the adoption of sandwich panels but also incentivizes manufacturers to innovate and improve their products, further enhancing market potential.