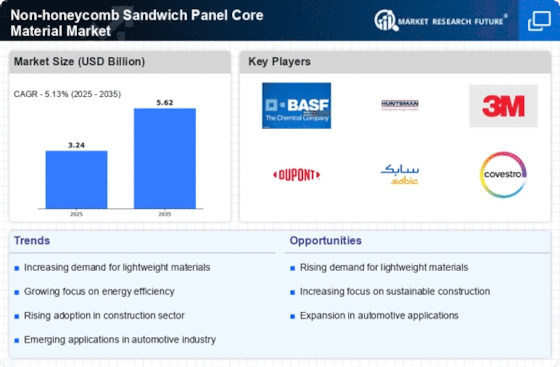

Growth in Construction Activities

The Non-honeycomb Sandwich Panel Core Material Market is poised for growth due to the ongoing expansion of construction activities worldwide. With urbanization and infrastructure development on the rise, there is an increasing need for efficient building materials. Non-honeycomb sandwich panels, known for their thermal insulation and structural integrity, are becoming a preferred choice in commercial and residential projects. In 2025, the construction sector is expected to witness a surge in demand for innovative materials that enhance energy efficiency. This trend suggests that non-honeycomb sandwich panels will play a crucial role in meeting the evolving needs of the construction industry, thereby driving market growth.

Increased Focus on Energy Efficiency

The Non-honeycomb Sandwich Panel Core Material Market benefits from a heightened focus on energy efficiency in various applications. As energy costs continue to rise, industries are increasingly adopting materials that contribute to energy savings. Non-honeycomb sandwich panels, with their excellent insulation properties, are well-positioned to meet this demand. In 2025, the market is likely to see a shift towards materials that not only provide structural benefits but also enhance energy performance. This trend indicates a growing recognition of the importance of energy-efficient solutions, which could lead to increased adoption of non-honeycomb sandwich panels in sectors such as construction and manufacturing.

Rising Demand for Lightweight Materials

The Non-honeycomb Sandwich Panel Core Material Market experiences a notable increase in demand for lightweight materials across various sectors, including construction and transportation. As industries strive for enhanced fuel efficiency and reduced emissions, lightweight materials become essential. The use of non-honeycomb sandwich panels, which offer superior strength-to-weight ratios, aligns with these objectives. In 2025, the market for lightweight materials is projected to grow significantly, driven by the automotive sector's shift towards electric vehicles. This trend indicates a potential for non-honeycomb sandwich panels to capture a larger share of the market, as manufacturers seek to optimize vehicle performance while adhering to stringent environmental regulations.

Technological Innovations in Manufacturing

The Non-honeycomb Sandwich Panel Core Material Market is influenced by ongoing technological innovations in manufacturing processes. Advances in production techniques enable the creation of more efficient and cost-effective non-honeycomb sandwich panels. These innovations may include the use of advanced composites and automated manufacturing systems, which enhance product quality and reduce production time. As manufacturers seek to improve their competitive edge, the adoption of these technologies is likely to increase. In 2025, the market may witness a rise in the availability of high-performance non-honeycomb sandwich panels, catering to diverse applications and driving overall market growth.

Regulatory Support for Sustainable Materials

The Non-honeycomb Sandwich Panel Core Material Market is positively impacted by regulatory support for sustainable materials. Governments worldwide are implementing policies that encourage the use of eco-friendly materials in construction and manufacturing. Non-honeycomb sandwich panels, often made from recyclable materials, align with these sustainability initiatives. In 2025, the market is expected to benefit from increased investments in sustainable building practices, driven by regulatory frameworks that promote energy efficiency and waste reduction. This regulatory support may lead to a greater acceptance of non-honeycomb sandwich panels, further propelling market growth.