Focus on Reducing Lead Times

Reducing lead times is becoming increasingly critical in the multi-tasking machine tools market, as companies strive to meet customer demands for faster delivery. The competitive landscape necessitates that manufacturers adopt strategies to streamline their production processes. Data indicates that companies that implement multi tasking-machine-tools can reduce lead times by up to 40%, allowing them to respond more swiftly to market changes. This focus on efficiency is driving investments in advanced machining technologies that facilitate quicker turnaround times without compromising quality. As a result, the multi tasking-machine-tools market is likely to see sustained growth as businesses prioritize the acquisition of tools that enhance their operational agility.

Growth in the Defense Sector

The defense sector is emerging as a significant driver for the multi-tasking machine tools market, particularly in the United States. With ongoing investments in military modernization and the development of advanced weaponry, there is a heightened demand for precision-engineered components. The U.S. defense budget for 2025 is projected to exceed $800 billion, which includes substantial allocations for procurement and research. This financial commitment suggests a robust market for multi tasking-machine-tools, as defense contractors require sophisticated machining solutions to produce complex parts efficiently. As a result, the multi tasking-machine-tools market is likely to see increased activity from defense-related projects, further bolstering its growth trajectory.

Emergence of Smart Manufacturing

The advent of smart manufacturing technologies is significantly influencing the multi-tasking machine tools market. The integration of IoT, AI, and data analytics into manufacturing processes is enabling companies to optimize their operations and enhance decision-making. This trend is expected to drive the demand for multi tasking-machine-tools that can seamlessly connect with smart systems. Research indicates that the smart manufacturing market is anticipated to reach $500 billion by 2025, suggesting a strong correlation with the growth of advanced machining tools. As manufacturers adopt these technologies, the multi tasking-machine-tools market is likely to experience a shift towards more intelligent and interconnected machining solutions, enhancing overall productivity and efficiency.

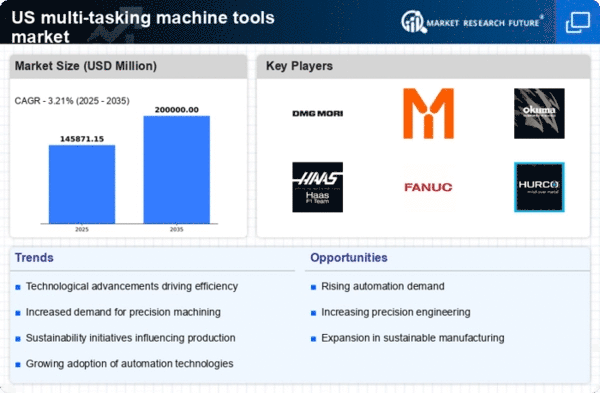

Increased Automation in Manufacturing

Automation is becoming a pivotal driver in the multi-tasking machine tools market, as manufacturers seek to enhance productivity and reduce operational costs. The integration of automated systems within machining processes allows for higher efficiency and consistency in production. Data suggests that the adoption of automation technologies in the manufacturing sector is expected to grow by 30% by 2026. This shift towards automation not only streamlines operations but also minimizes human error, thereby improving overall product quality. Consequently, the multi tasking-machine-tools market is likely to benefit from this trend, as companies invest in advanced machinery that supports automated workflows, ultimately leading to increased output and profitability.

Rising Demand for Precision Engineering

The multi-tasking machine tools market is experiencing a notable surge in demand driven by the increasing need for precision engineering across various sectors. Industries such as aerospace, automotive, and medical devices are particularly reliant on high-precision components, which multi tasking-machine-tools can efficiently produce. According to recent data, the aerospace sector alone is projected to grow at a CAGR of 4.5% through 2027, further fueling the need for advanced machining solutions. This trend indicates that manufacturers are increasingly investing in multi tasking-machine-tools to enhance their production capabilities and meet stringent quality standards. As a result, the market is likely to witness a robust expansion, with companies prioritizing the acquisition of sophisticated machinery to maintain competitive advantages.