Rising Focus on Safety Standards

The US Mechanical Control Cables Market is significantly influenced by the rising focus on safety standards across various sectors. Regulatory bodies are increasingly mandating stringent safety requirements for mechanical components, including control cables. This trend is particularly evident in the automotive and aerospace industries, where compliance with safety regulations is paramount. In 2025, it is estimated that compliance-related expenditures accounted for approximately 15% of the total market value. As manufacturers strive to meet these standards, the demand for high-quality, reliable mechanical control cables is expected to rise. This focus on safety not only enhances product reliability but also fosters innovation within the US Mechanical Control Cables Market, as companies seek to develop advanced solutions that adhere to evolving regulations.

Growing Demand in Automotive Sector

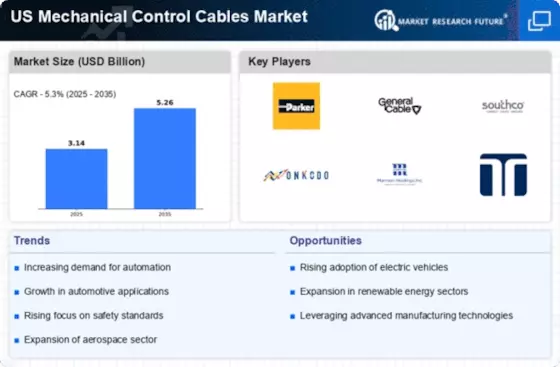

The US Mechanical Control Cables Market is experiencing a notable surge in demand, particularly driven by the automotive sector. As vehicle manufacturers increasingly prioritize safety and performance, the need for reliable control cables has intensified. In 2025, the automotive industry accounted for approximately 40% of the total demand for mechanical control cables in the US. This trend is likely to continue as electric vehicles gain traction, necessitating advanced control systems. Furthermore, the integration of automation in manufacturing processes is expected to enhance the efficiency of cable production, thereby supporting the growth of the market. The increasing focus on lightweight materials and improved cable designs may also contribute to the expansion of the US Mechanical Control Cables Market.

Expansion of Industrial Applications

The US Mechanical Control Cables Market is witnessing an expansion in industrial applications, which is significantly contributing to its growth. Industries such as aerospace, construction, and agriculture are increasingly utilizing mechanical control cables for various applications, including machinery control and automation. In 2025, the industrial sector represented around 30% of the market share, indicating a robust demand for these cables. The ongoing advancements in manufacturing technologies and the push for operational efficiency are likely to further drive the adoption of mechanical control cables across diverse industries. Additionally, the trend towards automation in industrial processes may lead to an increased requirement for specialized control cables, thereby bolstering the US Mechanical Control Cables Market.

Technological Innovations in Cable Design

The US Mechanical Control Cables Market is benefiting from technological innovations in cable design and manufacturing processes. Recent advancements, such as the development of high-strength materials and improved manufacturing techniques, have led to the production of more durable and efficient control cables. In 2025, it is projected that innovative cable designs will account for approximately 20% of the market growth, as manufacturers seek to enhance performance and reduce costs. These innovations are particularly relevant in sectors like aerospace and automotive, where performance and reliability are critical. The ongoing research and development efforts aimed at creating lightweight and flexible cables are likely to further propel the US Mechanical Control Cables Market, enabling it to meet the evolving demands of various applications.

Increased Investment in Infrastructure Development

The US Mechanical Control Cables Market is poised for growth due to increased investment in infrastructure development. Government initiatives aimed at enhancing transportation networks and public facilities are driving demand for mechanical control cables in construction and civil engineering projects. In 2025, infrastructure spending is expected to reach record levels, with a significant portion allocated to projects requiring reliable control systems. This trend is likely to create new opportunities for manufacturers of mechanical control cables, as they cater to the needs of various infrastructure projects. The emphasis on modernizing existing infrastructure and building new facilities may further stimulate the US Mechanical Control Cables Market, as the demand for high-quality control cables continues to rise.