Emergence of Industry 4.0

The emergence of Industry 4.0 is reshaping the landscape of the laser cutting-machines market. This new industrial revolution emphasizes smart manufacturing, where interconnected systems and data analytics play a crucial role. Laser cutting machines are increasingly being integrated into smart factories, allowing for real-time monitoring and optimization of production processes. The US manufacturing sector is investing heavily in digital technologies, with projections indicating a potential investment of over $500 billion in smart manufacturing by 2025. This shift towards digitalization is likely to enhance the capabilities of laser cutting machines, making them more efficient and versatile. As manufacturers adopt these advanced technologies, the demand for sophisticated laser cutting solutions is expected to rise, driving market growth.

Increased Investment in R&D

Increased investment in research and development (R&D) is a significant driver for the laser cutting-machines market. Companies are focusing on innovating and enhancing the capabilities of laser cutting technology to meet evolving industry needs. The US government has been promoting R&D initiatives, with funding for advanced manufacturing technologies reaching approximately $2 billion annually. This financial support is likely to encourage manufacturers to develop cutting-edge laser cutting machines that offer improved performance, energy efficiency, and versatility. As new technologies emerge, such as fiber lasers and hybrid systems, the market is expected to witness a transformation. This emphasis on R&D not only fosters innovation but also positions the laser cutting-machines market for sustained growth in the coming years.

Growth in the Aerospace Sector

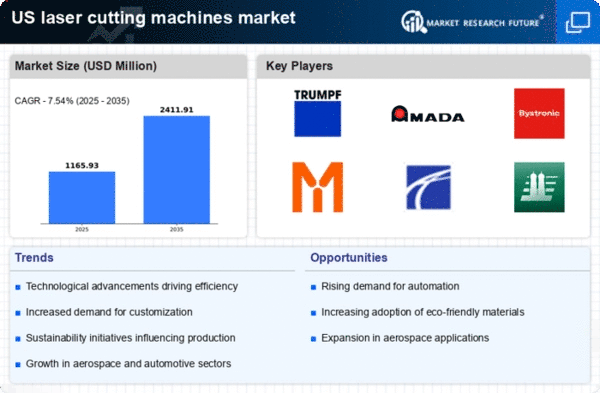

The aerospace sector's expansion is significantly influencing the laser cutting-machines market. With the increasing demand for lightweight and high-strength materials, laser cutting technology is essential for fabricating complex components with precision. The US aerospace industry is expected to reach a market value of $1 trillion by 2025, which indicates a robust growth trajectory. This growth is likely to necessitate advanced laser cutting solutions that can handle various materials, including composites and metals. As aerospace manufacturers seek to optimize their production processes, the reliance on laser cutting machines is expected to intensify, thereby propelling market growth. The ability of these machines to deliver intricate designs and reduce waste aligns with the industry's focus on efficiency and sustainability.

Rising Automation in Manufacturing

The increasing trend towards automation in manufacturing processes is a pivotal driver for the laser cutting-machines market. As industries strive for efficiency and precision, the adoption of automated systems is becoming more prevalent. This shift is particularly evident in sectors such as automotive and aerospace, where laser cutting technology enhances production speed and accuracy. According to recent data, the automation market in the US is projected to grow at a CAGR of approximately 10% over the next five years. This growth is likely to propel the demand for advanced laser cutting machines, which are integral to automated production lines. Consequently, manufacturers are investing in laser cutting technology to remain competitive, thereby driving the overall market forward.

Surge in Demand for Metal Fabrication

The surge in demand for metal fabrication services is a critical driver for the laser cutting-machines market. Industries such as construction, automotive, and electronics are increasingly relying on laser cutting technology to produce high-quality metal components. The US metal fabrication market is projected to grow at a CAGR of around 5% through 2026, reflecting a strong demand for precision-engineered parts. Laser cutting machines offer advantages such as reduced material waste and enhanced cutting speed, making them a preferred choice for fabricators. As companies strive to meet the growing demand for customized metal products, the adoption of laser cutting technology is likely to increase, further stimulating the market. This trend underscores the importance of laser cutting machines in modern manufacturing processes.