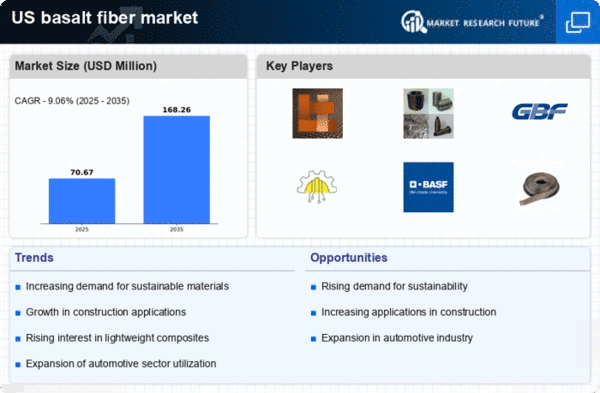

The basalt fiber market is currently characterized by a dynamic competitive landscape, driven by increasing demand for lightweight, high-strength materials across various industries, including construction, automotive, and aerospace. Key players such as Basalt Fiber Tech (RU), Mafic (IS), and BASF (DE) are strategically positioning themselves through innovation and regional expansion. Basalt Fiber Tech (RU) focuses on enhancing its production capabilities, while Mafic (IS) emphasizes sustainable practices in its manufacturing processes. BASF (DE) is leveraging its extensive research and development resources to introduce advanced basalt fiber composites, thereby shaping a competitive environment that prioritizes technological advancement and sustainability.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. The market structure appears moderately fragmented, with several players vying for market share. However, the collective influence of major companies is significant, as they drive trends in product development and market penetration strategies. This competitive structure fosters an environment where innovation and operational efficiency are paramount for success.

In October Mafic (IS) announced the opening of a new manufacturing facility in the United States, aimed at increasing its production capacity by 30%. This strategic move is likely to enhance its market presence and reduce shipping costs, thereby improving its competitive edge. The facility is expected to utilize advanced technologies that align with the company’s commitment to sustainability, potentially setting a new standard in the industry.

In September BASF (DE) launched a new line of basalt fiber-reinforced composites designed for the automotive sector. This product line is anticipated to reduce vehicle weight by up to 15%, contributing to improved fuel efficiency. The introduction of these composites reflects BASF's focus on innovation and its ability to respond to the growing demand for lightweight materials in the automotive industry, which is crucial for meeting regulatory standards and consumer expectations.

In August Basalt Fiber Tech (RU) entered into a strategic partnership with a leading construction firm to develop basalt fiber-reinforced concrete solutions. This collaboration is expected to enhance the durability and sustainability of construction materials, aligning with global trends towards greener building practices. The partnership signifies a strategic alignment that could lead to significant advancements in construction technology, positioning Basalt Fiber Tech as a leader in this niche market.

As of November the competitive trends in the basalt fiber market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are becoming more prevalent, as companies recognize the value of collaboration in driving innovation and market growth. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability, suggesting a transformative shift in how companies position themselves in the market.