Rising Demand for Coatings

The Thermal Spray Market experiences a notable increase in demand for protective coatings across various sectors. Industries such as aerospace, automotive, and energy are increasingly adopting thermal spray coatings to enhance the durability and performance of components. For instance, the aerospace sector utilizes thermal spray coatings to protect engine parts from extreme temperatures and wear. This trend is supported by data indicating that the thermal spray coatings segment is projected to grow at a compound annual growth rate of approximately 6.5% over the next few years. As industries seek to improve the longevity of their products, the demand for thermal spray coatings is likely to continue its upward trajectory.

Increasing Focus on Energy Efficiency

The Thermal Spray Market is influenced by a growing emphasis on energy efficiency and sustainability. Industries are increasingly adopting thermal spray coatings to improve the energy efficiency of their equipment and machinery. For example, thermal spray coatings can reduce friction and wear in mechanical systems, leading to lower energy consumption and extended service life. This trend aligns with broader sustainability initiatives, as companies seek to minimize their environmental impact. Market data suggests that the energy efficiency segment within the thermal spray industry is expected to expand, driven by regulatory pressures and consumer demand for greener technologies.

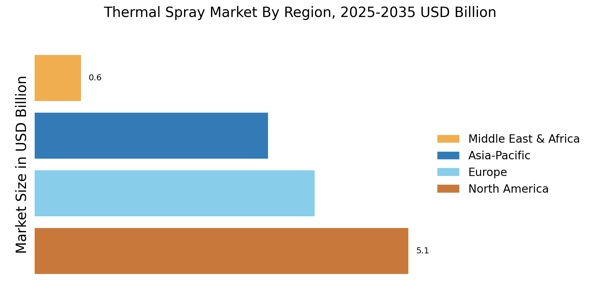

Emerging Markets and Industrialization

The Thermal Spray Market is poised for growth due to the industrialization of emerging markets. Countries in Asia and South America are experiencing rapid industrial development, leading to increased investments in manufacturing and infrastructure. This industrial growth drives the demand for thermal spray coatings, as industries seek to enhance the performance and durability of their products. Additionally, the rising awareness of advanced coating technologies among manufacturers in these regions is likely to further propel market growth. As these emerging markets continue to develop, the thermal spray industry is expected to benefit from the expanding opportunities in various applications.

Advancements in Thermal Spray Technology

Technological innovations play a crucial role in shaping the Thermal Spray Market. Recent advancements in thermal spray techniques, such as High Velocity Oxygen Fuel (HVOF) and Plasma Spray, have significantly improved the efficiency and effectiveness of coating applications. These technologies enable the deposition of coatings with superior adhesion and microstructure, which enhances the performance of coated components. Furthermore, the integration of automation and robotics in thermal spray processes is streamlining operations, reducing labor costs, and increasing production rates. As a result, the market is witnessing a shift towards more sophisticated thermal spray solutions, which are expected to drive growth in the coming years.

Expansion of Aerospace and Defense Sectors

The Thermal Spray Market is significantly impacted by the expansion of the aerospace and defense sectors. As these industries continue to grow, the demand for high-performance materials and coatings is increasing. Thermal spray Market coatings are essential for protecting critical components in aircraft and military equipment from corrosion, wear, and high temperatures. The aerospace sector alone is projected to witness a substantial increase in spending, which is likely to boost the demand for thermal spray applications. This growth presents opportunities for manufacturers and service providers within the thermal spray market, as they cater to the evolving needs of these sectors.