Market Analysis

In-depth Analysis of Super Absorbent Polymer Market Industry Landscape

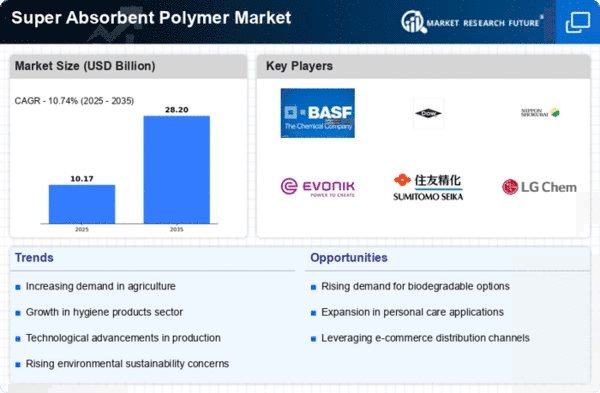

The Super Absorbent Polymer (SAP) market is growing due to dynamic factors, such as applications in hygiene products, agriculture, and the medical sector, among others. Super Absorbent Polymers are materials capable of absorbing large amounts of water or aqueous solutions with unique characteristics. One of the major drivers shaping market dynamics is demand within the hygiene products industry. Market dynamics in Super Absorbent Polymers are influenced significantly by agricultural activities. SAPs are used as soil conditioners and water retaining agents in agriculture, aimed at improving water efficiency as well as enhancing soil water-holding capacity. This aspect helps save water, particularly in arid areas prone to drought, thereby ensuring sustainable agricultural practices and increased crop yield. Standards of regulation and environmental considerations greatly shape the dynamics of the Super Absorbent Polymer market. Compliance with regulations on hygiene products' safety and performance, as well as their impact on the environment, affect SAP formulation and application. Cost-effectiveness is a key determinant of how the Super Absorbent Polymer industry operates. Industries are interested in cost-effective solutions. At the same time, it offers an absorbency level that is without any compromise on performance to meet SAP needs, thus striking out a balance between production costs and productivity of their goods. The Market Dynamics Of Super Absorbent Polymers Are Also Affected By Global Economic Factors. Fluctuations in economics can affect consumer spending on hygiene products and agricultural practices, as well as the general demand for SAPs. Technological advancements have a significant influence in shaping the dynamic landscape of the Super Absorbent Polymer Market. This leads to ongoing research and development (R&D) activities aimed at discovering innovative ways through which new SAP formulations could be achieved in order to enhance properties and biodegradability can be improved or find other innovative applications. The medical field also contributes to market dynamics regarding superabsorbent polymers. Currently, conventional superabsorbent polymers form most non-biodegradable materials found in landfills worldwide, hence posing a big ecological challenge leading to investment towards developing superabsorbent polymers made from renewable materials, which will open up new routes within global markets.

Leave a Comment