Refrigeration Insulation Materials Size

Refrigeration Insulation Materials Market Growth Projections and Opportunities

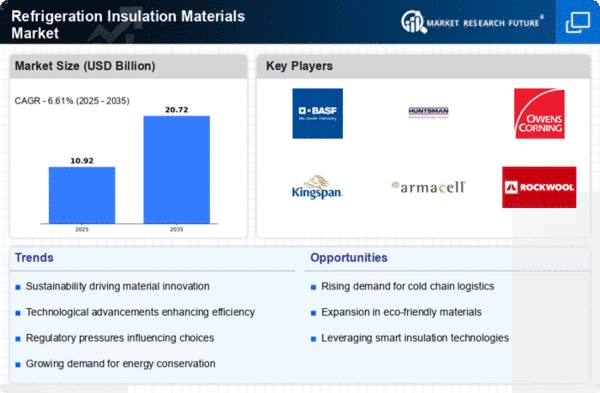

The market size of the Refrigeration Insulation Materials Market is influenced greatly by a plethora of market forces which shape its dynamics and trajectory of growth. Among these, the increasing demand for energy efficient and eco-friendly solutions is one of the key drivers. In response to global shift towards sustainability, industrial trends now show a preference towards insulation materials that save energy and have low carbon emissions. The need for this kind of material increases due to strict guidelines and regulations on energy consumption in refrigeration systems which have forced industries into spending on better insulation materials.

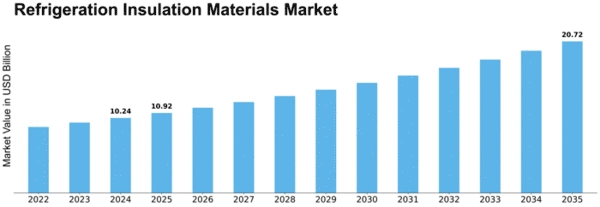

The analysis conducted by MRFR indicated that it is expected that by 2027, the Refrigeration Insulation Materials Market will grow at a CAGR of over 5% with an estimation to reach approximately USD 5 Billion.

Technological advancements are another crucial factor shaping the market landscape. This continuous innovation in insulation materials has been made possible through research activities thereby improving their performance and thermal efficiency. Manufacturers are striving to find materials with improved thermal conductivity, durability, and environmental resistance. Thus, such inventions not only serve the dynamic demands of today’s refrigeration industry but also give businesses within the market a competitive advantage.

Moreover, factors like economic fluctuations, currency exchange rates etc., also affect the overall economic environment thus affecting purchasing power both for businesses as well as consumers who use them. Demand for insulation materials goes up during periods when economies are growing strongly owing to increased expenditure on infrastructure including refrigeration systems. Conversely, during economic downturns there may be reduced construction activities or capital investments making it unfavorable in terms of business conditions.

Furthermore geographical distribution of demand becomes another important variable underpinning the size. Places where extreme climate conditions prevail for example very cold winters or extremely hot summers experience higher levels of demand for cooling systems hence; requiring more effective insulating substances. Additionally urbanization trends as well as population growth rate enhance demand for refrigerating solutions thereby boosting its uptake among other aspects.

Additionally, refrigeration insulation materials market is significantly affected by the availability and price of raw materials. Numerous insulating products are manufactured using petrochemicals hence, they become vulnerable to oil price fluctuations. To stay stable and competitive on the market manufacturers pay close attention to changes in cost of raw materials. Also, geopolitical issues as well as supply chain disruptions can affect the availability of these inputs into the market and thereby raising some uncertainties.

The Refrigeration Insulation Materials Market is strongly influenced by governmental policies and regulations. Environmental policies aimed at reducing greenhouse gas emissions and promoting energy efficiency are driving use of green insulation materials. The market dynamics are also influenced by subsidies, incentives as well as tax advantages targeted on corporations engaging in eco-friendly practices thus providing a conducive environment for insulation material producers’ growth.

Consumer’s awareness and preferences have changed over time with more emphasis being put on sustainability and product performance. Such customers are better informed about environmental consequences related to different types of insulating substances and therefore select those that match their principles during shopping process. Therefore, this change in consumer behavior has led many companies towards sustainable practices hence resulting into an increase in demand for eco-friendly insulation materials.

Leave a Comment