Market Share

Refrigeration Insulation Materials Market Share Analysis

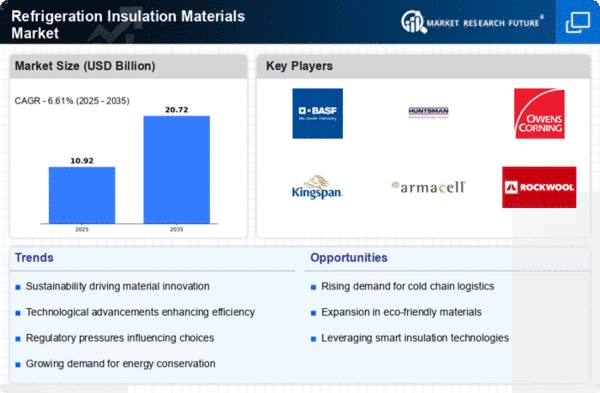

The Refrigeration Insulation Materials Market is a live and competitive industry where companies use different market share positioning tactics to create an edge over others. One of the most popular strategies employed in this industry is differentiation that enables firms to uniquely offer insulation materials. However, with state-of-the-art technology or environmentally friendly and energy efficient materials, they can appeal to selective clientele. It also gives the firm dominance since it specializes in high-performance insulation solutions.

Besides, cost leadership is a common strategy used by various companies to become lowest producers in the market. For instance, through optimizing production processes, sourcing for materials effectively and achieving economies of scale, they are able to sell their insulation materials at competitive prices. This strategy targets those customers who are price sensitive while on the other hand such companies can take large portions of their market due to its appeal to cost-conscious consumers as well. Nonetheless, it is important for firms pursuing this approach to strike a balance between low cost and quality products that meet relevant standards.

The refrigeration insulation material market also highly relies on segmentation as one of its key aspects in relation to positioning of market shares. Companies can choose specific segments like residential, commercial or industrial applications among others within the market only. As such they get more share within these areas especially if they tailor the products and marketing techniques for particular sections alone thereby availing more customized products for each group’s unique needs (Kaufmann & Dean 2017). Additionally, these actions enable them understand what different customers require hence establishing themselves better than before in aimed-for sectors.

In addition there has been increased collaboration and strategic partnerships as means of positioning market shares in the refrigeration insulation material industry. These may involve working together with original equipment manufacturers (OEMs), contractors or distributors who collaborate with them thereby widening their scope while improving on their delivery system respectively (Wang et al., 2013). Consequently through alliances with strategic partners; businesses can expand their base as they access new markets and ultimately enlarge their shares. Moreover, such partnerships equally support innovations within organizations via sharing resources as well as skills.

Technological advancement is directly linked to market share positioning strategies in the refrigeration insulation material industry. Companies that invest in research and development to create advanced insulation materials with superior thermal efficiency, durability, and environmental sustainability gain a competitive advantage. Keeping at pace with technological developments helps businesses respond to changing customer requirements and standards of the industry hence making them leaders in the market.

Leave a Comment