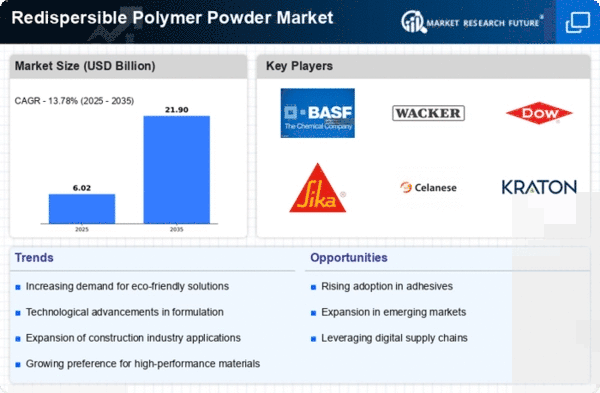

Top Industry Leaders in the Redispersible Polymer Powder Market

The redispersible polymer powder market is a dynamic and rapidly growing space. Understanding the competitive landscape, key strategies, and recent developments is crucial for companies to navigate this exciting market and capture market share. By focusing on product innovation, regional expansion, sustainability initiatives, and digitalization

Competitive Strategies:

-

Product Diversification: Leading companies like Wacker Chemie, BASF, and Evonik Industries are expanding their portfolios beyond standard vinyl acetate-ethylene (VAE) powders. They are introducing specialty redispersible polymers with enhanced functionalities like improved water resistance, flame retardancy, and adhesion, catering to niche applications. -

Regional Expansion: The Asia-Pacific region is experiencing a construction boom, driving demand for redispersible polymer powders. Players like Kuraray Co. and Nippon Shokubai are aggressively expanding their presence in this region through acquisitions, partnerships, and greenfield investments. -

Sustainability Focus: Environmental consciousness is shaping the market. Companies are developing bio-based redispersible polymers using renewable resources like corn starch and cellulose. Henkel, for example, launched its Natureplus line of bio-based powders, targeting eco-conscious consumers. -

Technological Innovation: Continuous advancements in polymer science are leading to the development of redispersible powders with superior performance characteristics, such as higher dispersion rates, lower film shrinkage, and improved compatibility with various binders. Evonik Industries' VISCOMAT® range exemplifies this trend. -

Digitalization: Embracing digital tools like online sales platforms, data analytics, and customer relationship management (CRM) systems is becoming increasingly important. Companies like Bostik are utilizing these tools to optimize their supply chains, personalize marketing strategies, and improve customer service.

Factors Influencing Market Share:

-

Brand Reputation: Established players like Wacker Chemie and BASF enjoy a strong brand reputation for their high-quality products and consistent performance. This gives them a significant edge over smaller competitors. -

Regional Market Dynamics: The growth potential varies across regions. Asia-Pacific is currently the fastest-growing market, followed by Europe and North America. Companies with a strong presence in these regions are likely to gain market share. -

Product Differentiation: Offering unique and innovative redispersible polymer powders with specific functionalities caters to specific customer needs, opening doors for market share expansion. -

Price Competitiveness: Cost-effective production processes and efficient distribution channels give manufacturers a competitive advantage, particularly in price-sensitive markets. -

Sustainability Initiatives: Companies showcasing commitment to sustainability through bio-based products and eco-friendly manufacturing processes are attracting environmentally conscious consumers and businesses, boosting their market share.

The prominent key players in this market outlook are the following:

- Divnova Specialities (India)

- Akzo Nobel N.V (Netherlands)

- Ashland Global Holding (U.S)

- Hexicon Inc (U.S)

- Synthomer Plc (UK)

- Wacker Chemie AG (Germany)

- Puyang

Recent Developments

This RDP was designed for one-component (1K) premium-performance waterproofing mortars called Mowilith® POWDER 2702, which were launched in 2024 by Archroma. It enhances the adhesion, hydrophobicity, and semi-flexibility of cementitious formulations, which reduces mortar cracking and improves overall sealing performance (Specialty chemicals).

Celanese’s Elotex Line includes multiple kinds of re-dispersible polymer powders used in various applications in the construction industry. These are shell polymers that improve the properties of dry mix mortars, such as adhesion, flexibility, and durability. Tile adhesives, self-leveling compounds, exterior insulation, and finish systems (EIFS) are some of its applications (Celanese).

Redispersion polymers from Kemox, like RDPs, can quickly disperse into emulsions that are comparable to initial emulsion properties. These change elasticity, weather resistance, and adhesion to diverse substrates, thus suited to improving the performance of tiling adhesives, mortars, and waterproofing membranes (HPMC RDP With Affordable Price).